Membrane distillation system

This year, more than a third of the world will suffer from shortages of potable water. This number is expected to rise by 50% by 2025 and that’s one of the reasons why the desalination techniques of seawater are so important, because they will allow coastal communities to address local shortfalls.

The new technology was developed by Kamalesh Sirkar, a chemical engineer from the New Jersey Institute of Technology, and it’s comprised of a direct-contact membrane distillation system (DCMD) that will distill drinking water out of up to 20% salt-concentrated brine. After 25%, the salt precipitates out of the solution and could damage the system.

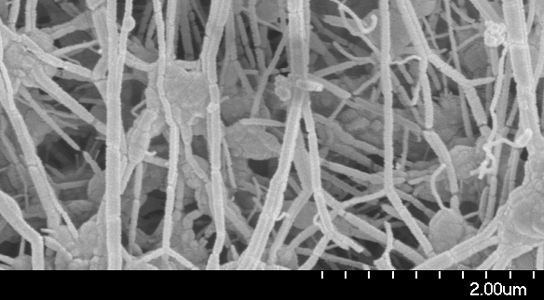

The salt concentration of normal seawater is 3.5%, meaning that the system can reprocess the same water several times. Heated seawater flows across a membrane strung between a series of hollow tubes that are made out of a porous yet hydrophobic fiber. This means that only water vapor can be osmotically transferred. Cold distillate water runs through each of the tubes in a direction that’s perpendicular to the seawater, allowing for a temperature gradient. This gradient causes the vapor to form on the tubes. The vapor diffuses through the pores and condenses inside of them, joining the flow of cold distillate water.

The salt is not able to penetrate the tubes. With each cycle, more fresh water is drawn away and the resulting brine is more concentrated. Sirkar’s patented system can deliver 80 L of drinking water from 100 L of seawater. Usual techniques yield about 41 L from the same amount of seawater. This membrane distillation requires a steady source of heat.

The salt is not able to penetrate the tubes. With each cycle, more fresh water is drawn away and the resulting brine is more concentrated. Sirkar’s patented system can deliver 80 L of drinking water from 100 L of seawater. Usual techniques yield about 41 L from the same amount of seawater. This membrane distillation requires a steady source of heat.

Be the first to comment on "New Desalination Membrane Technology Promises to Be More Efficient"