Plywood and other composite wood products are used extensively in home construction, furniture, and decor. They are often made using glues and resins that contain potentially carcinogenic chemicals such as formaldehyde.

The go-to materials for building home furniture, décor, and floors are composite wood products that come in large sheets. But the glues and resins holding together particleboard, fiberboard, and plywood usually contain formaldehyde and could release this probable carcinogen into the air. To develop a non-toxic adhesive, researchers reporting today (May 11, 2022) in ACS Applied Materials & Interfaces have combined glucose and citric acid — sugar and an orange juice ingredient — into a strong, water-resistant wood glue for plywood.

To make plywood, manufacturers glue together thin layers of wood and then cure the material under pressure and heat, creating large, flexible panels. One of the most popular adhesives to use in this application is a urea-formaldehyde resin because it’s inexpensive and bonds strongly to wood. However, formaldehyde emissions from plywood with this type of resin have raised health and environmental concerns. Previous studies have shown that solutions of sucrose, a two-unit sugar made of glucose and fructose, and citric acid form a natural and water-resistant wood glue. However, a zinc chloride catalyst is required to decrease the energy consumption for the plywood curing, which also reduces the adhesive’s strength. So, Hong Lei and colleagues wanted to see if pure glucose and citric acid could create a strong adhesive with a less energy-intensive curing process.

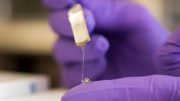

Citric acid and glucose produce a wood glue that creates strong, water-resistant three-layer plywood. Credit: Adapted from ACS Applied Materials & Interfaces 2022, DOI: 10.1021/acsami.2c02859

The researchers heated solutions of glucose and varying amounts of citric acid into a sticky liquid that they applied onto poplar veneers. Then they stacked three veneers and pressed them into a single sheet at 392° F (200° C) for six minutes. The team cut the sheets into smaller pieces for strength tests and found that under pressures greater than 101 psi, the plywood samples all broke along the wood fibers and not at the glued seams.

These results satisfy the standard requirement for plywood in China. When the plywood samples were soaked in hot or boiling water, only the ones made with citric acid to glucose ratios above 0.6 had adhesive strengths that satisfied the standard requirement. The researchers attribute these results to the increase in ester links between citric acid and wood, which increased the wood-binding strength and water-resistance.

Citric acid-glucose adhesives hold promise for the wood products industry, the researchers say.

Reference: “Fully biobased adhesive from glucose and citric acid for plywood with high performance” by Chunyin LI, Hong LEI, Zhigang WU, Xuedong XI, Guanben DU and Antonio Pizzi, 11 May 2022, ACS Applied Materials & Interfaces.

DOI: 10.1021/acsami.2c02859

The authors acknowledge funding from the National Natural Science Foundation of China, the Yunnan Provincial Natural Science Foundation, the 111 project and the French National Research Agency (ANR).

Be the first to comment on "Chemists Develop a Non-Toxic Glue for Plywood – From Glucose and Citric Acid"