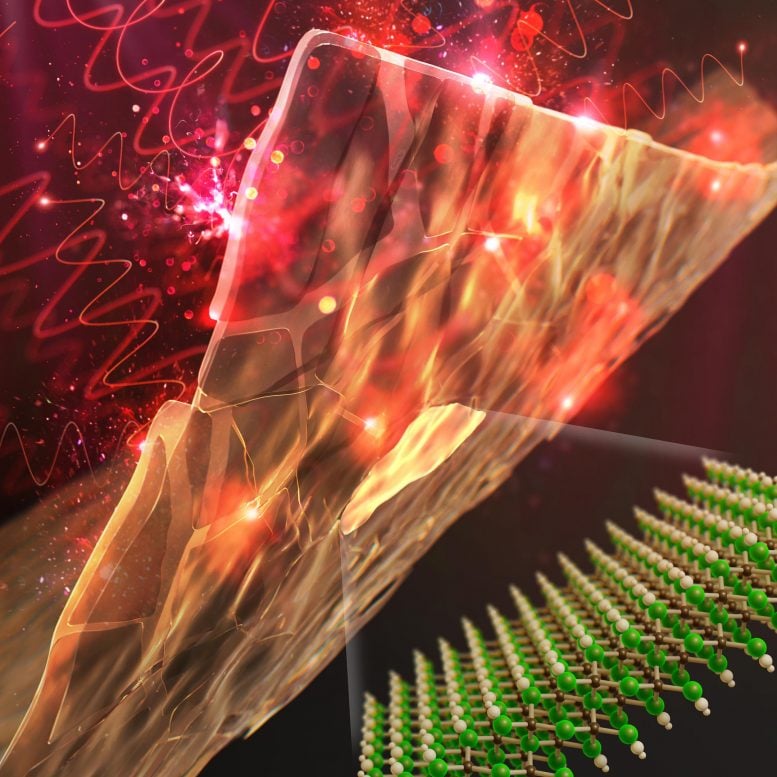

(Click image for full view.) Uniform Nanometer-thick MXene films can be used as electromagnetic shields in flexible electronics and 5G telecommunication devices. Credit: Korea Institute of Science and Technology (KIST)

Uniform nanometer-thick MXene* films can be used as electromagnetic shields in flexible electronics and 5G telecommunication devices.

A Korean research team has developed a technology to fabricate an ultrathin material for electromagnetic interference (EMI) shielding. The research team, led by Koo Chong-Min, the head of the Materials Architecturing Research Center at the Korea Institute of Science and Technology (KIST, Acting President Yoon Seok-jin), announced that it had developed an ultrathin nanometer-thick film, using MXene, a new two-dimensional nanomaterial for EMI shielding. The research was jointly conducted with a team led by Professor Kim Sang-ouk of the Department of Materials Science and Engineering at Korea Advanced Institute of Science and Technology (KAIST, President: Shin Sung-chul) and a research team led by Professor Yury Gogotsi from Drexel University, USA.

Micrometer thick MXene films with high electrical conductivity, reported by Koo Chong-min in 2016, presented outstanding electromagnetic interference shielding. However, there were no technologies that could be used to directly apply MXene to highly integrated electronic devices, such as h5G communications and mobile devices.

*MXene: A 2D nano material with the same level of electrical conductivity (10,000 S/cm) as metals. Reported by a research team led by Koo Chong-Min, head of the Materials Architecturing Research Center, KIST, the higher a material’s electrical conductivity, the higher its electromagnetic interference shielding performance (Science 353, Issue 6304, pp. 1137-1140).

The KIST-KAIST-Drexel joint research team used self-assembly technique to fabricate an ultrathin MXene film with uniform atomic-scale thickness. MXene film is reported to have exceptional absolute electromagnetic shielding performance (shielding effectiveness relative to thickness and density) that is far greater than that of any other material reported to date.

By adding a volatile solution onto the surface of a diluted MXene solution, the research team was able to induce floating MXene flakes. Vertical convection, resulting from differences in surface tension, caused the self-assembly of the micron-sized MXene flakes, thereby creating a large-size ultrathin MXene film with uniform atomic-scale thickness. The research team found that MXene films layered to reach 55 nm in thickness provide 99% electromagnetic shielding efficiency. Ultrathin MXene films fabricated using the team’s new technology can easily be transferred onto any substrate and layered multiple times for customized thickness, transmittance, and surface resistance.

“We used a self-assembly technique to fabricate an ultrathin Ti3C2Tx MXene film with uniform atomic-scale thickness. This technology helped to examine the electromagnetic shielding mechanism of nanometer-thick 2D nano materials and to develop an ultrathin electromagnetic shielding application technology for flexible electronics,” said Koo Chong-Min, the head of the Materials Architecturing Research Center at KIST. “We believe that the ultrathin coated MXene technology can be applied to various electronic devices and be used for mass production, thereby facilitating research on the application of next-generation lightweight electromagnetic shielding and flexible and printable electronics.”

Reference: “Electromagnetic Shielding of Monolayer MXene Assemblies” by Taeyeong Yun, Hyerim Kim, Aamir Iqbal, Yong Soo Cho, Gang San Lee, Myung‐Ki Kim, Seon Joon Kim, Daesin Kim, Yury Gogotsi, Sang Ouk Kim and Chong Min Koo, 23 January 2020, Advanced Materials.

DOI: 10.1002/adma.201906769

The research, supported by Korea’s Ministry of Science and ICT (Minister Choi Ki-young), was conducted as one of KIST’s key projects, through the KIST Research Laboratory Project, the Research Leader Support Project (Multi-Dimensional Nano Assembly and Control Creative Research Group); and the NNFC-Drexel-SMU International Joint Research Project. An article explaining the findings of the research was published on the inside front cover of the latest issue of the science journal “Advanced Materials” (Adv. Mater. 2020, 32, 1906769; IF: 25.809, top 1.042% of JCR).

Be the first to comment on "Nanometer-Thick Electromagentic Shielding Film Developed Using MXene"