Technicians are simultaneously manufacturing NASA’s Space Launch System (SLS) core stages for the Artemis II and Artemis III lunar missions at NASA’s Michoud Assembly Facility in New Orleans. The core stage for the deep space rocket consists of two huge propellant tanks, four RS-25 engines, and miles of cabling for the avionics systems and flight computers. All the main core stage structures for Artemis II, the first mission with astronauts, have been built and are being outfitted with electronics, feedlines, propulsion systems, and other components. Technicians are currently wiring and performing functional tests on the avionics inside both the forward skirt and intertank sections. The engine section – the most complicated part of the stage – is in production assembly.

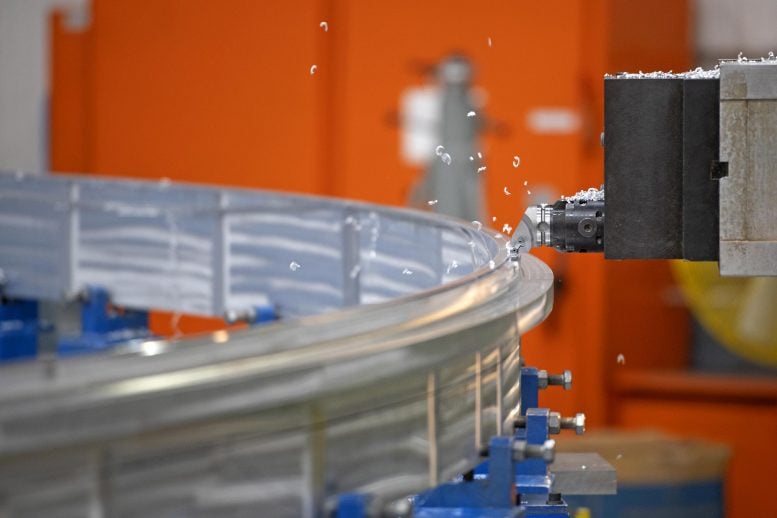

Engineers are welding the core stage structures for the Artemis III mission, which will land the first woman and the next man on the lunar surface, through a process called friction stir welding. Each of the structures for the core stage has rings that attach the pieces together to produce one stage during final assembly. The rings are trimmed down to 1/1000th of an inch at the ring machining center then sent to another part of the facility for the next phase of manufacturing. Assembling the 5.5-million-pound SLS rocket for the Artemis missions takes special tools and is a collaborative effort between NASA and Boeing, the lead contractor for the core stage.

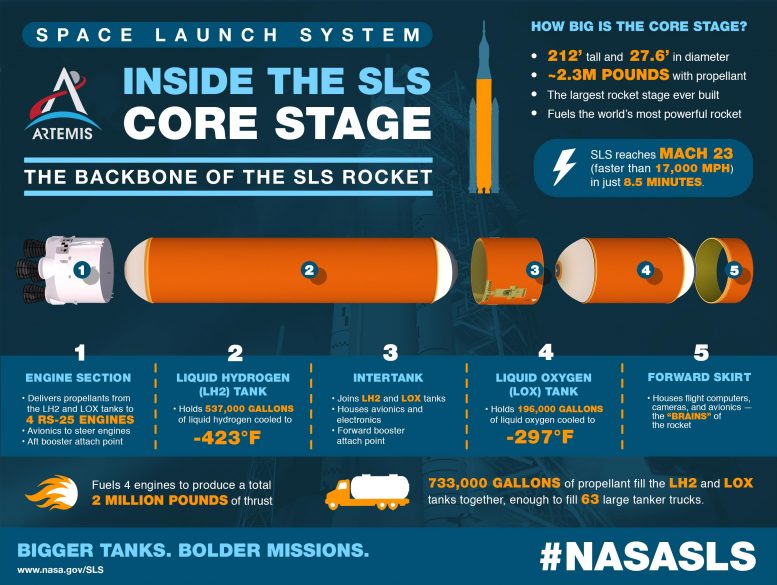

We need the biggest rocket stage ever built for the bold missions in deep space that NASA’s Space Launch System rocket will give us the capability to achieve. This infographic sums up everything you need to know about the SLS core stage, the 212-foot-tall stage that serves as the backbone of the most powerful rocket in the world. The core stage includes the liquid hydrogen tank and liquid oxygen tank that hold 733,000 gallons of propellant to power the stage’s four RS-25 engines needed for liftoff and the journey to Mars. Credit: NASA/MSFC

The manufacturing progress for Artemis II and III comes as the first core stage for the SLS rocket undergoes Green Run testing at NASA’s Stennis Space Center in Bay St. Louis, Mississippi. NASA is working to land the first woman and the next man on the Moon by 2024. The SLS rocket, NASA’s Orion spacecraft, Gateway, and human landing system are part of NASA’s backbone for deep space exploration. The Artemis program is the next step in human space exploration. It’s part of America’s broader Moon to Mars exploration approach, in which astronauts will explore the Moon. Experience gained there will enable humanity’s next giant lap: sending humans to Mars. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission.

Very Interesting.

Putting on my Risk Management Avatar.

I am sure the engineers must have already built in multiple fail safe backup systems and the ability to self-repair any hitches in such a complex project/. Also – work around capability in case of multiple failures which is a very remote probability. The Risks should be less an a old man or a three year old crossing a a busy intersection in Manhattan during peak traffic!

See that Oxygen tank has been tested. Miles of cables is a worry. Electronics need to be 100% reliable and tested and have sufficient coponents on board in case of multiple failures in case it needs to be fixed. I hope the nine futuremissions will take supplies to the Lumar Surface and use it as the base / backup facility for Launching lomger distance space flights. Ability to approve and fix technology with groundengineers who built artemis and are the real master needs to maintained at multiple places including Houston and Florida needs to be integral to these missions. Buisness continuity planning may requireother facilities which are backups to the brain the real controller on other continents for longer space travel.

Best of Luck!