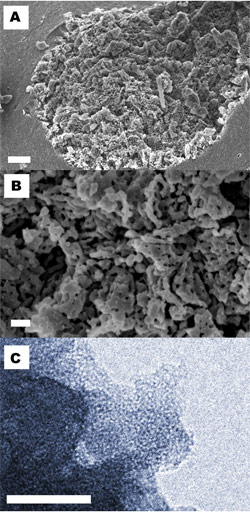

Electron microscopy images of Upsalite. a) SEM micrograph of Upsalite. Scale bar, 1µm. b) Higher magnification SEM of a region in a) clearly showing the textural porosity of the material. Scale bar, 200 nm. c) Representative TEM image of Upsalite showing contrast consistent with a porous material. The image is recorded with under-focused conditions to enhance the contrast from the pores. Scale bar, 50 nm. Credit: Disruptive Materials

Researchers from Uppsala University have developed a magnesium carbonate material with record breaking properties.

A novel material with world record breaking surface area and water adsorption abilities has been synthesized by researchers from Uppsala University, Sweden. The results are published today in PLOS ONE.

The magnesium carbonate material that has been given the name Upsalite is foreseen to reduce the amount of energy needed to control environmental moisture in the electronics and drug formulation industry as well as in hockey rinks and warehouses. It can also be used for collection of toxic waste, chemicals, or oil spills and in drug delivery systems, for odor control and sanitation after fire.

“In contrast to what has been claimed for more than 100 years in the scientific literature, we have found that amorphous magnesium carbonate can be made in a very simple, low-temperature process”, says Johan Goméz de la Torre, a researcher at the Nanotechnology and Functional Materials Division.

While ordered forms of magnesium carbonate, both with and without water in the structure, are abundant in nature, water-free disordered forms have been proven extremely difficult to make. In 1908, German researchers claimed that the material could indeed not be made in the same way as other disordered carbonates, by bubbling CO2 through an alcoholic suspension. Subsequent studies in 1926 and 1961 came to the same conclusion.

“A Thursday afternoon in 2011, we slightly changed the synthesis parameters of the earlier employed unsuccessful attempts, and by mistake left the material in the reaction chamber over the weekend. Back at work on Monday morning we discovered that a rigid gel had formed and after drying this gel we started to get excited”, says Johan Goméz de la Torre.

A year of detailed materials analysis and fine-tuning of the experiment followed. One of the researchers got to take advantage of his Russian language skills since some of the chemistry details necessary for understanding the reaction mechanism were only available in an old Russian PhD thesis.

“After having gone through a number of state-of-the-art materials characterization techniques it became clear that we had indeed synthesized the material that previously had been claimed impossible to make”, says Maria Stromme, professor of nanotechnology and head of the nanotechnology and functional materials division.

The most striking discovery was, however, not that they had produced a new material but it was instead the striking properties they found that this novel material possessed. It turned out that Upsalite had the highest surface area measured for an alkali earth metal carbonate; 800 square meters per gram.

“This places the new material in the exclusive class of porous, high surface area materials including mesoporous silica, zeolites, metal organic frameworks, and carbon nanotubes”, says Stromme.

“In addition, we found that the material was filled with empty pores all having a diameter smaller than 10 nanometers. This pore structure gives the material a totally unique way of interacting with the environment leading to a number of properties important for application of the material.”

Upsalite is for example found to absorb more water at low relative humidities than the best materials presently available; the hydroscopic zeolites, a property that can be regenerated with less energy consumption than is used in similar processes today.

“This, together with other unique properties of the discovered impossible material is expected to pave the way for new sustainable products in a number of industrial applications”, says Maria Stromme.

The discovery will be commercialized through the University spin-out company Disruptive Materials (www.disruptivematerials.com) that has been formed by the researchers together with the holding company of Uppsala University.

Reference: “A Template-Free, Ultra-Adsorbing, High Surface Area Carbonate Nanostructure” by Johan Forsgren, Sara Frykstrand, Kathryn Grandfield, Albert Mihranyan and Maria Strømme, 17 July 2013, PLOS ONE.

DOI: 10.1371/journal.pone.0068486

Be the first to comment on "Researchers Develop Record Breaking Magnesium Carbonate Material"