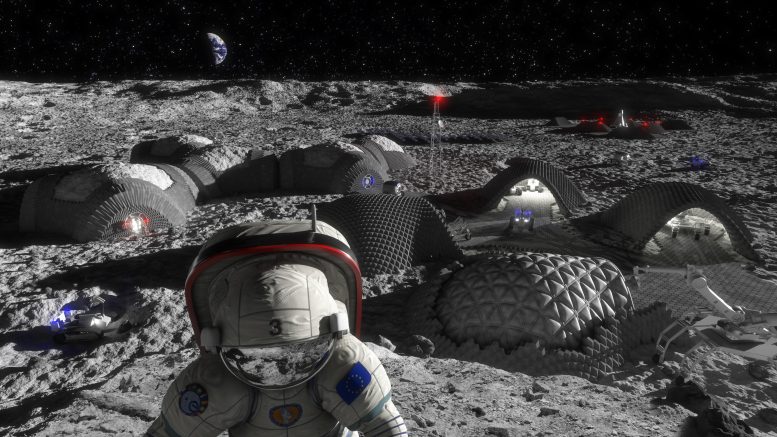

A vision of a future Moon base that could be produced and maintained using 3D printing. Credit: RegoLight, visualisation: Liquifer Systems Group, 2018

Humanity’s ambition to establish a sustained presence on the Moon relies on leveraging in-situ resource utilization (ISRU) technologies to build infrastructure and produce vital resources like water and oxygen directly from lunar materials. Research, led by ESA’s Discovery & Preparation program, has progressed from fundamental studies in the late 1990s to recent advancements in 3D printing habitats and producing oxygen from simulated moondust.

Humanity is heading back to the Moon, and this time, we’re planning to stay. But for long-term space missions, astronauts would need infrastructure to live and work, to move around, to communicate with Earth, and to produce oxygen and water vital for survival. Taking all this infrastructure from Earth would likely be prohibitively expensive. Instead, we need to figure out how to make it on site. ESA Discovery & Preparation has supported many studies to explore how we can do this.

Using local materials to build infrastructure and produce amenities is known as in-situ resource utilization (ISRU). Past research in this area has explored and demonstrated fundamental ISRU concepts using a combination of resources found on the exploration site and materials brought from Earth.

By testing the market for transport services to the Moon, ESA aims to push the limits of technology and create new models of space business. Credit: ESA

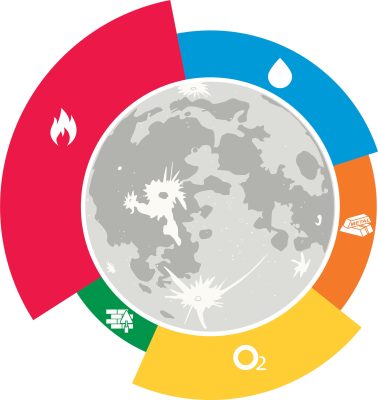

ISRU is needed to build a habitat that shields astronauts from harsh environments including thin or non-existent atmospheres, extreme temperatures, intense radiation, and even micrometeoroids. It would enable us to build roads to move around the surface, and launch and landing pads for traveling to and from Earth. It could be used to produce equipment that can generate and store energy for producing electricity, as well as antenna towers for communication. And it could produce huge amounts of water and oxygen for keeping astronauts alive and creating propellants for traveling around and eventually coming back to Earth.

Discovery & Preparation activities

In 1999, one of the first ISRU-related Discovery & Preparation studies focused on propulsion and power systems, assessing the needs for advanced propulsion in the current century. The study concluded that ISRU could reduce the costs of missions to Mars whilst increasing our capabilities, but that research and development in ISRU technologies should begin right away.

And so, in coordination with all ESA programs, research continued. A study completed in 2000 focused on the power systems required for future space exploration, including designing an ISRU chemical plant to produce propellant, chemicals for life support, and fuel for surface activities.

Other studies happening at the same time took a broader look at long-term space exploration, with one considering what architectures and technologies would be required for Mars exploration. The study investigated the possibility of producing propellant and fluids necessary for crew survival – including nitrogen, oxygen, hydrogen and water – from the Martian atmosphere and soil. Another study on the survivability and adaptability of humans to long-duration interplanetary and planetary environments also found that ISRU could be particularly useful for producing propellants and life support consumables.

Fast forwarding 13 years, the technology had developed enough to explore more specific ISRU concepts, including a system to collect and store carbon dioxide from the Martian atmosphere and deliver it to a propulsion system. The study, carried out by Airbus, suggested ways in which dust and water could be removed from the carbon dioxide, as well as how it could be liquified for storage.

Over the last few years, Discovery & Preparation has supported more research into building infrastructure using lunar soil and more specific methods of energy generation and storage; a recent study explored how lunar regolith could be used to store heat and provide electricity for astronauts, rovers, and landers.

Setting up a future lunar base could be made much simpler by using a 3D printer to build it from local materials. Industrial partners including renowned architects Foster+Partners joined ESA to test the feasibility of 3D printing using lunar soil. Credit: ESA/Foster + Partners

One study explored how lunar analog facilities could support the development of ISRU technologies, including testing the excavation and processing of local materials, as well as how these materials could be used to build structures using processes like 3D printing.

Another confirmed the suitability of lunar soil as a building material, selected a suitable process for printing structures from it, and even designed a printable habitat. And a third recently went one step further and explored how any necessary structures, equipment, and spare parts could be 3D printed using lunar regolith, even selecting which specific printing processes would work best.

As an alternative to existing 3D printing technologies, a 2019 study looked into turning lunar soil into fibers to build strong structures. The researchers produced a sample of material to show that it is possible to use this process to make structures that are locally impermeable.

A set of Discover & Preparation studies recently explored and defined ESA’s lunar IRSU demonstration mission, which aims to prove by 2025 that producing water or oxygen on the Moon is possible. These studies looked into the system that would actually produce the water and oxygen, proposing a package that extracts oxygen from the soil and uses it to produce water, using a ‘carbo-thermal reactor’. Another explored how the system could rely on a lander as a power supply and a third investigated how it could communicate with Earth.

What else is ESA doing?

To implement the lunar ISRU demonstration mission, ESA intends to procure mission-enabling services from the commercial sector, including payload delivery, communication, and operations services. In doing so, ESA will both leverage on and further nurture existing commercial initiatives that may find widespread applications in a future lunar exploration scenario.

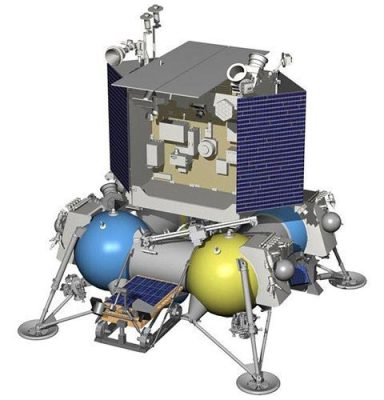

ESA is also currently working on the PROSPECT mission, which will access and assess potential resources on the Moon to prepare for the technologies that may be used to extract these resources in the future. PROSPECT will drill beneath the Moon’s surface near its South Pole and extract samples expected to contain frozen water and other chemicals that can become trapped at extremely low temperatures. The drill will then pass the samples to a chemical laboratory where they will be heated to extract these chemicals. The mission will operate as part of the Russian-led Luna-27 mission and will test processes that could be applied to resource extraction in the future.

To support the ambition to have a human presence on the Moon sustained by local resources by 2040, in May 2019, ESA published its Space Resources Strategy. The strategy considers what we need to discover and develop to support sustainable space exploration. The strategy covers the period up to 2030, by which time the potential of lunar resources will have been established through measurements at the Moon, key technologies will have been developed and demonstrated and a plan for their introduction into international mission architectures will have been defined. Following the publication of the strategy, ESA hosted a workshop to identify the next steps needed to make space resource utilization a reality.

Producing oxygen and metal out of simulated moondust inside ESA’s Materials and Electrical Components Laboratory. Credit: ESA–A. Conigili

In 2020, ESA set up a prototype plant to produce oxygen out of simulated moondust. Removing the oxygen from lunar soil leaves various metals; another line of research, therefore, is to see what are the most useful alloys that could be produced from them, and how they could be used on the Moon. The ultimate aim would be to design a ‘pilot plant’ that could operate sustainably on the Moon, with the first technology demonstration targeted for the mid-2020s.

What are other space agencies doing in this area?

NASA’s Lunar Reconnaissance Orbiter already indicated the presence of water ice buried under the lunar soil at certain locations. The orbiter launched with the Lunar CRater Observation and Sensing Satellite that was released from the orbiter and impacted the Moon; observations of the resulting 16-kilometer-high plume showed the chemical make-up of the lunar surface.

The US Agency is also developing several CubeSat orbital missions that will visit the Moon. Lunar Flashlight, LunaH-MAP, and Lunar IceCube will aim to find out how much water ice there is and where exactly it can be found.

NASA’s first Mars lander, Viking, returned important data about the Martian atmosphere, revealing that it is made up of 95.9 percent carbon dioxide. Based on this discovery and information returned by subsequent robotic missions, the Agency has developed technologies to convert Mars’ atmospheric carbon dioxide into oxygen to benefit human missions to the red planet. Recently, NASA selected the Mars Oxygen In-Situ Resource Utilization Experiment, or MOXIE, as one of seven instruments on the Mars Perseverance rover.

Volatiles are substances that vaporize easily and could be a source of water on the Moon. Together with other space agencies, NASA is conducting an international coordination of lunar polar volatiles exploration to increase scientific knowledge, determine the viability of volatiles as potential resources, and to use the Moon as a proving ground for Mars ISRU technologies.

Future China National Space Administration missions are also expected to target lunar polar volatiles as potential resources. China’s vision of an international lunar research station, to be established initially as a robotic facility for science and research during the late 2020s and early 2030s may provide an early opportunity for lunar resources to be utilized.

The Russian space agency, Roscosmos, is working with ESA on the series of three Luna missions, including Luna-27, which will host ESA’s PROSPECT package. The mission will target measurements in the polar region of the Moon, focusing on cold trapped volatiles that may be found there.

What’s next at ESA?

Through its Open Space Innovation Platform (OSIP), ESA sought ideas on enabling technologies for in-situ construction, manufacturing, and maintenance of infrastructure and hardware to support long-term exploration of a planetary body.

The proposed ideas support the construction of habitats, mobility infrastructure (e.g. roads and landing pads), ancillary infrastructure (e.g. for communication and energy generation and storage), and hardware (e.g. tools, interior equipment, machinery, and clothing).

An idea submitted to the Open Space Innovation Platform (OSIP) proposed that orbital debris could be used for in-situ resource manufacturing on the Moon. Credit: ESA/Orbit Recycling

Ideas include many novel methods for melting and 3D printing lunar soil, making solar cells from lunar soil, optimizing energy storage, finding methods to grow plants from organic waste without needing soil, using lunar soil to build crop-friendly greenhouses, and building infrastructure using space debris. Many of the ideas are now being implemented by ESA as studies, co-funded research projects, or early technology development projects. To find out more, visit the results section of this call for ideas.

The use of space resources for exploration is now within reach thanks to advances in our knowledge and understanding of the Moon and asteroids, increased international and private sector engagement in space technologies, and the emergence of new technologies.

Developing technologies and methods to use local resources to support future astronauts remains a challenge, but in doing so we are stimulating innovation on Earth through technology needs as well as new approaches to managing limited resources. This will hopefully help us find new ways to address global challenges and generate near to mid-term economic returns for terrestrial industries.

What is 1+1

i’ve not seen any proposals for doming over craters, it would seem to be a perfect solution, protected by the crater walls, probably access to tubes, good garage for equipment storage…