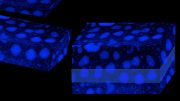

Using fluorescence to demonstrate how particles bind differently to different types of materials. Credit: Morgan Alexander

Some polymers can resist bacteria; can they be designed to work against viruses?

Personal protective equipment, like face masks and gowns, is generally made of polymers. But not much attention is typically given to the selection of polymers used beyond their physical properties.

To help with the identification of materials that will bind to a virus and speed its inactivation for use in PPE, researchers from the University of Nottingham, EMD Millipore, and the Philipps University of Marburg developed a high-throughput approach for analyzing the interactions between materials and viruslike particles. They report their method in the journal Biointerphases, from AIP Publishing.

“We’ve been very interested in the fact that polymers can have effects on cells on their surface,” said Morgan Alexander, an author on the paper. “We can get polymers, which resist bacteria, for example, without designing any particular clever or smart material with antibiotic in there. You just have to choose the right polymer. This paper extends this thinking to viral binding.”

The group created microarrays of 300 different monomer compositions of polymers representing a wide variety of characteristics. They exposed the polymers to Lassa and Rubella viruslike particles — particles with the same structure as their viral counterparts but without the infectious genomes activated — to see which materials were able to preferentially adsorb the particles.

“Knowing that different polymers bind and possibly inactivate viruses to different degrees means we may be able to make recommendations. Should I use this existing glove material or that glove if I want the virus to bind to it and die and not fly into the air when I take the gloves off?” Alexander said.

Though this may seem like an obvious method for quickly screening large quantities of materials, the team’s interdisciplinary makeup makes them uniquely positioned to conduct such a study. The surface scientists have the capabilities to create large numbers of chemicals on microarrays, and the biologists have access to virus-like particles.

So far, the tests have only looked at virus-like particles of Lassa and Rubella, but the group is hoping to acquire a grant to look at virus-like particles of SARS-CoV-2, the COVID-19 virus.

Once a handful of the best-performing materials have been determined, the next step of the project will be to use live viruses to evaluate the viral infectious lifetime on the materials, taking into account real-world environmental conditions, like humidity and temperature. With enough data, a molecular model can be built to describe the interactions.

“Strong binding and quick denaturing of a virus on a polymer would be great,” said Alexander. “It remains to be seen whether the effect is significantly large to make a real difference, but we need to look to find out.”

Reference: “Polymer microarrays rapidly identify competitive adsorbents of virus-like particles” by Andrew J. Blok, Pratik Gurnani, Alex Xenopoulos, Laurence Burroughs, Joshua Duncan, Richard A. Urbanowicz, Theocharis Tsoleridis, Helena Müller, Thomas Strecker, Jonathan K. Ball, Cameron Alexander and Morgan R. Alexander, 17 November 2020, Biointerphases.

DOI: 10.1116/6.0000586

Be the first to comment on "Seeking the Most Effective Virus-Resistant Polymers for Personal Protective Equipment"