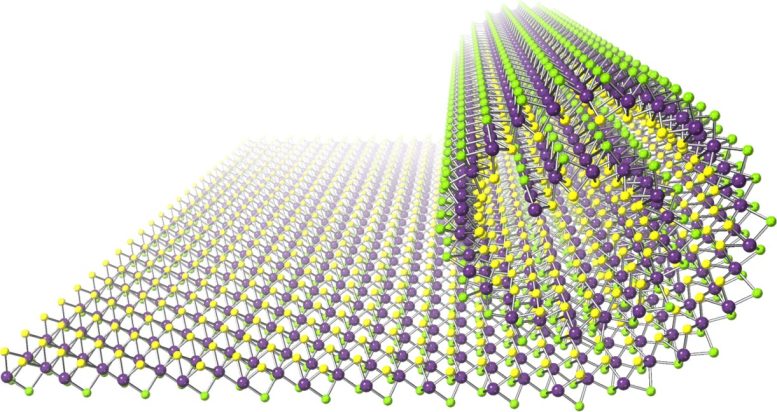

By replacing the atoms on one side of the nanosheet with a different element, the team has realized a nanosheet that can spontaneously roll into a scroll when detached from its substrate. Credit: Tokyo Metropolitan University

Janus nanosheets bring unprecedented control to preparation of nanoscrolls.

Researchers from Tokyo Metropolitan University have come up with a new way of rolling atomically thin sheets of atoms into “nanoscrolls.” Their unique approach uses transition metal dichalcogenide sheets with a different composition on either side, realizing a tight roll that gives scrolls down to five nanometers in diameter at the center and micrometers in length. Control over the nanostructure in these scrolls promises new developments in catalysis and photovoltaic devices.

Advancements in Nanotechnology

Nanotechnology is giving us new tools to control the structure of materials at the nanoscale, promising a whole nano-toolset for engineers to create next-generation materials and devices. At the forefront of this movement, a team led by Associate Professor Yasumitsu Miyata of Tokyo Metropolitan University has been studying ways to control the structure of transition metal dichalcogenides (TMDC), a class of compounds with a wide range of interesting properties, such as flexibility, superconductivity, and unique optical absorbance.

A New Method for Nanoscroll Production

In their latest work, they set their sights on new ways of making nanoscrolls, nanosheets rolled up into tight scroll-like structures. This is an attractive approach for making multi-walled structures: since the structure of each sheet is the same, the orientations of individual layers are aligned with each other.

However, the two existing ways of making nanoscrolls have significant issues. In one, removing sulfur atoms from the surface of the nanosheet creates distortions that cause the sheet to roll up; but by doing so, they destroy the crystal structure of the sheet. In the other, a solvent is introduced between the nanosheet and the substrate, loosening the sheet from the base and allowing the formation of defect-free nanoscrolls. However, tubular structures made like this tend to have large diameters.

Breakthrough With Janus Nanosheets

Instead of approaches like this, the team have come up with a new way of causing sheets to roll up. Starting with a monolayer molybdenum selenide nanosheet, they treated the nanosheet with a plasma and replaced the selenium atoms on one side with sulfur; such structures are called Janus nanosheets, after the ancient two-faced god. Gentle addition of a solvent then loosens the sheets from the base, which then spontaneously roll into scrolls due to the asymmetry between the sides.

These new nanoscrolls are multiple microns in length, significantly longer than previously made single-walled TMDC nanosheets. Furthermore, they were found to be more tightly rolled than ever before, with a center down to five nanometers in diameter, meeting theoretical expectations. The scrolls were also found to interact strongly with polarized light and have hydrogen-producing properties.

Implications for Future Technologies

This novel method of creating TMDC nanoscrolls paves the way for significant research into their applications in catalysis and photovoltaic devices. The ability to precisely control the nanostructures of these scrolls heralds new possibilities for the development of advanced materials and technologies.

Reference: “Nanoscrolls of Janus Monolayer Transition Metal Dichalcogenides” by Masahiko Kaneda, Wenjin Zhang, Zheng Liu, Yanlin Gao, Mina Maruyama, Yusuke Nakanishi, Hiroshi Nakajo, Soma Aoki, Kota Honda, Tomoya Ogawa, Kazuki Hashimoto, Takahiko Endo, Kohei Aso, Tongmin Chen, Yoshifumi Oshima, Yukiko Yamada-Takamura, Yasufumi Takahashi, Susumu Okada, Toshiaki Kato and Yasumitsu Miyata, 17 January 2024, ACS Nano.

DOI: 10.1021/acsnano.3c05681

Funding: Japan Science and Technology Agency, Japan Society for the Promotion of Science, the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Yazaki Memorial Foundation for Science and Technology, Mitsubishi Foundation, The Murata Science Foundation Research Grant, The Cooperative Research Project Program of the Research Institute of Electrical Communication, Tohoku University

These scrolls would make great reinforcement for metals, or other materials. Likely they could be mixed into molten steel. I wonder what would happen to the Se, and S at molten steel temperatures. There might be a problem with carbon absorption into the melt from the scrolls. Orientation, length, and dispersion in the matrix would vary the composite material strength under normal, and shear stress. stress units of MPa

If these Nano-Scrolls could be electrically superconducting, it might be possible to use electric power line cables made of this material, to indirectly stop global warming. The reason WHY we cannot use electric power generated by clean energy systems in isolated areas, to empower cities far away from these mountain tops or ocean energy sites, is that the electrical resistance of conventional copper and Aluminum wire cable wastes a great deal of the electric juice in heat. Also such long distance clean power setups require expensive, massive transmission step-up depots along the many miles long power cable routes to the cities where the juice is needed, and a cheap superconducting alternative like this could make that unnecessary!