Researchers have developed a cost-effective method to produce smart textiles, incorporating LEDs, sensors, energy harvesting, and storage, using conventional industrial looms. The technique overcomes limitations in functionality, dimensions, and shapes by weaving electronic, optoelectronic, sensing, and energy fiber components with traditional fibers. This enables the creation of smart textiles with no size or shape restrictions, providing an alternative to larger electronics in various sectors. By collaborating with textile manufacturers, the team produced test patches of smart textiles, with potential for scaling up in size and volume. Further optimization is required, but the researchers believe this approach could make large, flexible displays and monitors more affordable and environmentally friendly.

An international research team led by the University of Cambridge has developed a cost-effective and eco-friendly method for producing smart textiles using industrial looms. This technique enables the creation of flexible, durable smart fabrics with no size or shape limitations, offering potential applications across various industries.

Researchers have developed next-generation smart textiles – incorporating LEDs, sensors, energy harvesting, and storage – that can be produced inexpensively, in any shape or size, using the same machines used to make the clothing we wear every day.

The international team, led by the University of Cambridge, have previously demonstrated that woven displays can be made at large sizes, but these earlier examples were made using specialized manual laboratory equipment. Other smart textiles can be manufactured in specialized microelectronic fabrication facilities, but these are highly expensive and produce large volumes of waste.

However, the team found that flexible displays and smart fabrics can be made much more cheaply, and more sustainably, by weaving electronic, optoelectronic, sensing and energy fiber components on the same industrial looms used to make conventional textiles. Their results, reported in the journal Science Advances, demonstrate how smart textiles could be an alternative to larger electronics in sectors including automotive, electronics, fashion and construction.

Despite recent progress in the development of smart textiles, their functionality, dimensions and shapes have been limited by current manufacturing processes.

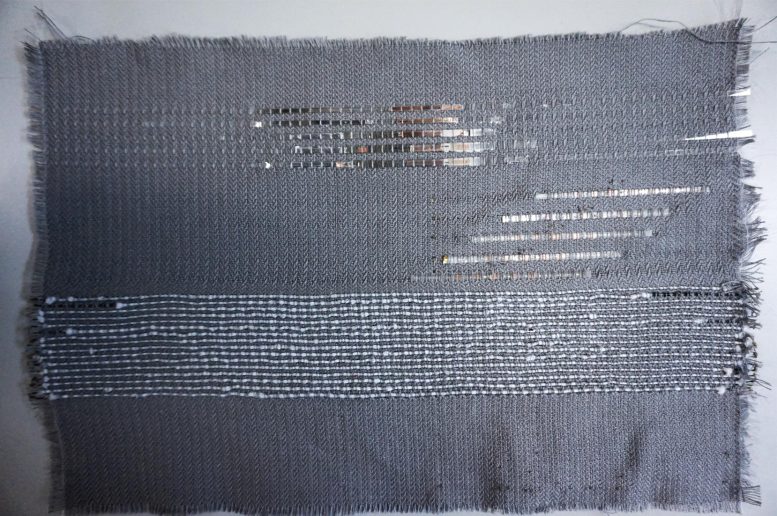

Researchers have developed next-generation smart textiles – incorporating LEDs, sensors, energy harvesting, and storage – that can be produced inexpensively, in any shape or size, using the same machines used to make the clothing we wear every day. Credit: Sanghyo Lee

“We could make these textiles in specialized microelectronics facilities, but these require billions of pounds of investment,” said Dr. Sanghyo Lee from Cambridge’s Department of Engineering, the paper’s first author. “In addition, manufacturing smart textiles in this way is highly limited, since everything has to be made on the same rigid wafers used to make integrated circuits, so the maximum size we can get is about 30 centimeters in diameter.”

“Smart textiles have also been limited by their lack of practicality,” said Dr. Luigi Occhipinti, also from the Department of Engineering, who co-led the research. “You think of the sort of bending, stretching and folding that normal fabrics have to withstand, and it’s been a challenge to incorporate that same durability into smart textiles.”

Last year, some of the same researchers showed that if the fibers used in smart textiles were coated with materials that can withstand stretching, they could be compatible with conventional weaving processes. Using this technique, they produced a 46-inch woven demonstrator display.

Researchers have developed next-generation smart textiles – incorporating LEDs, sensors, energy harvesting, and storage – that can be produced inexpensively, in any shape or size, using the same machines used to make the clothing we wear every day. Credit: Sanghyo Lee

Now, the researchers have shown that smart textiles can be made using automated processes, with no limits on their size or shape. Multiple types of fiber devices, including energy storage devices, light-emitting diodes, and transistors were fabricated, encapsulated, and mixed with conventional fibers, either synthetic or natural, to build smart textiles by automated weaving. The fiber devices were interconnected by an automated laser welding method with electrically conductive adhesive.

The processes were all optimized to minimize damage to the electronic components, which in turn made the smart textiles durable enough to withstand the stretching of an industrial weaving machine. The encapsulation method was developed to consider the functionality of the fiber devices, and the mechanical force and thermal energy were investigated systematically to achieve the automated weaving and laser-based interconnection, respectively.

The research team, working in partnership with textile manufacturers, were able to produce test patches of smart textiles of roughly 50×50 centimeters, although this can be scaled up to larger dimensions and produced in large volumes.

“These companies have well-established manufacturing lines with high throughput fiber extruders and large weaving machines that can weave a meter square of textiles automatically,” said Lee. “So when we introduce the smart fibers to the process, the result is basically an electronic system that is manufactured exactly the same way other textiles are manufactured.”

The researchers say it could be possible for large, flexible displays and monitors to be made on industrial looms, rather than in specialized electronics manufacturing facilities, which would make them far cheaper to produce. Further optimization of the process is needed, however.

“The flexibility of these textiles is absolutely amazing,” said Occhipinti. “Not just in terms of their mechanical flexibility, but the flexibility of the approach, and to deploy sustainable and eco-friendly electronics manufacturing platforms that contribute to the reduction of carbon emissions and enable real applications of smart textiles in buildings, car interiors and clothing. Our approach is quite unique in that way.”

Reference: “Truly form-factor—free industrially scalable system integration for electronic textile architectures with multifunctional fiber devices” by Sanghyo Lee, Hyung Woo Choi, Cátia Lopes Figueiredo, Dong-Wook Shin, Francesc Mañosa Moncunill, Kay Ullrich, Stefano Sinopoli, Petar Jovancic, Jiajie Yang, Hanleem Lee, Martin Eisenreich, Umberto Emanuele, Salvatore Nicotera, Angelo Santos, Rui Igreja, Alessio Marrani, Roberto Momentè, João Gomes, Sung-Min Jung, Soo Deok Han, Sang Yun Bang, Shijie Zhan, William Harden-Chaters, Yo-Han Suh, Xiang-Bing Fan, Tae Hoon Lee, Jeong-Wan Jo, Yoonwoo Kim, Antonino Costantino, Virginia Garcia Candel, Nelson Durães, Sebastian Meyer, Chul-Hong Kim, Marcel Lucassen, Ahmed Nejim, David Jiménez, Martijn Springer, Young-Woo Lee, Geon-Hyoung An, Youngjin Choi, Jung Inn Sohn, SeungNam Cha, Manish Chhowalla, Gehan A. J. Amaratunga, Luigi G. Occhipinti, Pedro Barquinha, Elvira Fortunato, Rodrigo Martins and Jong Min Kim, 21 April 2023, Science Advances.

DOI: 10.1126/sciadv.adf4049

The research was supported in part by the European Union and UK Research and Innovation.

Be the first to comment on "Threads of Innovation: Cheaper Method for Making Woven Displays and Smart Fabrics"