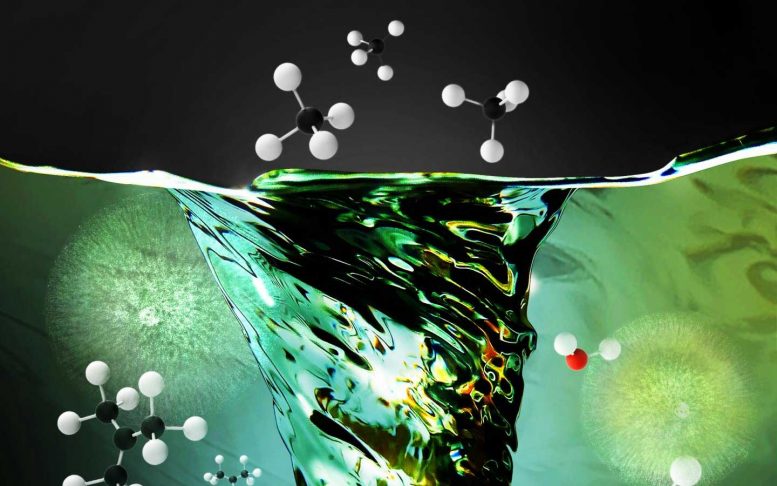

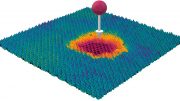

Atomic layer deposition (ALD) involves stacking layers of atoms on top of each other like pancakes. The atoms come from a vaporized material called a precursor. ASD is a well-established technique for manufacturing microelectronics like semiconductors and magnetic heads for sound recording, as well as sensors for bioengineering and diagnostics.

However, using ALD for depositing layers on larger surfaces has been a struggle, especially when it comes to manufacturing materials that must be kept at low cost, e.g. catalysts and solar devices.

“The sticking point is not necessarily making the right material but making it cheaply,” explains Professor Jeremy Luterbacher, head of EPFL’s Laboratory of Sustainable and Catalytic Processing (LPDC). “Coating larger surface areas with gas-phase methods requires long deposition times, and huge excesses of precursor, both of which increase costs,” adds Benjamin Le Monnier, the Ph.D. student who performed most of the research.

Now, the LPDC has developed a solution. Using ALD in a liquid phase, the scientists can produce materials indistinguishable from those made in the gas phase, with far cheaper equipment and no excess precursors.

Greater precision cuts costs

The researchers achieved this breakthrough by carefully measuring the ratio of the reacting precursors before injecting them onto the surface of a substrate. This way, they used exactly the right amount of precursor, with no leftovers that can cause unwanted reactions or be wasted.

The new method also reduces costs by requiring only standard lab equipment for chemical synthesis. It can also be easily scaled up to coat more than 150 g of material with the same cheap equipment, without loss of coating quality. The technique can even achieve coatings that are not possible using gas-phase ALD, e.g. by using non-volatile precursors.

“We believe that this technique could greatly democratize the use ALD on catalysts and other high surface area materials,” says Luterbacher.

This research was published yesterday (November 11, 2019) in the journal Advanced Materials.

Reference: “Atomic layer deposition on dispersed materials in liquid phase by stoichiometrically limited injections” by Benjamin P. Le Monnier, Frederick Wells, Farzaneh Talebkeikhah and Jeremy S. Luterbacher, 11 November 2019, Advanced Materials.

DOI: 10.1002/adma.201904276

how close are we star trek replicator?

how close are we to the star trek replicator?