Electric vehicles traditionally take hours to charge, but a new anode material developed by Professor Won Bae Kim’s team at POSTECH can reduce this time to just six minutes. This advancement is due to the use of manganese ferrites nanosheets, synthesized through a unique method, improving battery capacity and charging speed.

Typically, it takes around 10 hours to charge an electric vehicle. Even with fast-charging techniques, you’re still looking at a minimum of 30 minutes – and that’s if there’s an open spot at a charging station. If electric vehicles could charge as swiftly as we refill traditional gas vehicles, it would alleviate the shortage of EV charging spots.

The efficiency of lithium-ion batteries, the type used in electric vehicles, is determined by the anode material’s capability to store lithium ions. Recently, Professor Won Bae Kim, from the Department of Chemical Engineering and the Graduate Institute of Ferrous & Energy Materials Technology at Pohang University of Science and Technology (POSTECH, President Moo Hwan Kim), led a research team to develop a new anode material.

The study was published as a front cover paper in Advanced Functional Materials. Credit: Advanced Functional Materials

His team, which included Ph.D. candidates Song Kyu Kang and Minho Kim from the Department of Chemical Engineering, synthesized manganese ferrites (Mn3-xFexO4) nanosheets using a novel self-hybridization method involving a straightforward galvanic replacement-derived process. This groundbreaking technique boosts storage capacity approximately 1.5 times above the theoretical limit and enables an electric vehicle to be charged in as little as six minutes. The research was recognized for its excellence and was published as a front-cover paper in the journal Advanced Functional Materials.

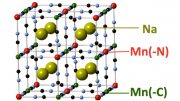

In this study, the research team devised a new method to synthesize manganese ferrites as anode material known for its superior lithium-ion storage capacity and ferromagnetic properties. First, a galvanic replacement reaction took place in a solution of manganese oxide mixed with iron, leading to a heterostructure compound with manganese oxide inside and iron oxide outside.

The team further used a hydrothermal method to create nanometer-thick sheets of manganese ferrites with expanded surface areas. This approach harnessed highly spin-polarized electrons, which significantly enhanced the storage capacity for a substantial quantity of lithium ions. This innovation allowed the team to effectively exceed the theoretical capacity of the manganese ferrites anode material by over 50 percent.

Enlarging the surface area of the anode material facilitated the simultaneous movement of a large quantity of lithium ions, thereby improving the battery’s charging speed. Experimental results showed that just six minutes are required to charge and discharge a battery with a capacity equivalent to that used in EVs currently on the market. This study has refined the challenging synthesis process to make a breakthrough in the theoretical capacity of the anode material and significantly accelerate the battery charging process.

Professor Won Bae Kim, who spearheaded the research, stated, “We have offered a new understanding of how to overcome the electrochemical limitations of conventional anode materials and increase battery capacity by applying the rational design with surface alteration using electron spin.” He expressed optimism that this development could lead to increased battery durability and reduced recharging time for electric vehicles.

Reference: “Exceeding Theoretical Capacity in Exfoliated Ultrathin Manganese Ferrite Nanosheets via Galvanic Replacement-Derived Self-Hybridization for Fast Rechargeable Lithium-Ion Batteries” by Song Kyu Kang, Minho Kim, Hyun Ho Shin, Wongeun Yoon, Seungjun Lee, Daehee Jang, Junil Choi, Gwan Hyeon Park, Jungsoo Park and Won Bae Kim, 26 February 2023, Advanced Functional Materials.

DOI: 10.1002/adfm.202300143

This research was conducted with the support of the Mid-Career Researcher Program the Advanced Research Center Program of the National Research Foundation of Korea the Ministry of Science and ICT, and the Ministry of Trade, Industry and Energy Program to Upgrade the Performance of Next Generation Rechargeable Lithium-ion Batteries and Develop New Manufacturing Technologies.

Your astrology ad is blocking the article. I can’t read it. It scrolls down with the page .

Man oh man nag uism

I think it’s a major game changer.

Design n chemistry ⚗️

Internal compbusion engines better than horse 🐎

Yes electric vehicles are a different design n chemistry ⚗️ fuel ⛽️ 👌 😎 👏 🙌 😀

That’s all nice and dandy and would be a big improvement, but there are side-effects. You would still need the power to charge the battery in that short amount of time, so the charge amps or voltage need to go up (and be produced somehow). Higher charge speeds will also produce a lot more heat. That could be a challenge because EV batteries already have a hard time with temperature.

Additionally, before being commercially viable, they need to demonstrate that the new anode construction doesn’t make the batteries anymore prone to self-ignition.

My thoughts exactly. Battery tech in general is getting better when it comes to charging speeds. Currently the average is about 30 min. As active cooling is perfected, even at today’s fast charging speeds, the drawback is the car’s charging curve. If I am was able to charge my Ev continuously at 300, I would be able to get to 80% from 10% in only 10 minutes. The Lucid for example has great range but is very slow to charge. The Porch Tycan has a much shorter range but has about the best charging curve out there. Tesla model s has really good range and really good charging speeds but the whole package works best for a road trip. Another few years and fast charging your EV will be about as fast as filling your gas tank only better as most folks charge at home while they are sleeping. Most folks don’t road trip more than a few times a year and even then it us usually under 1000 miles. So the amount of time spent charging as upposed to filling up with gas is probably, on average less than 3 hours per year.

What ever happened to pulse charging. I saw a almost totally dead, and shorted NmH Nicle metal hydride battery completely un-shorted, and recharged using this trick. I saw a Lead Acid battery that was completely sulphated, and basically dead, rejuvenated, and able to hold almost it’s original charge. It was about 30 years ago I saw this tech demonstrated.

I suppose we should look at the EVSE Tesla is charging their Semi trucks with, as well as their arrangements with the electrical suppliers. They have the most reliable EVSE performance reputation so far.

How can anything exceed the “theoretical limit” by any amount, especially 1.5 times? I was open to good news until I read that.

Sorry but a 6 min quick charge for a battery that size will never be a good charge. This will burn out batteries, give false hope to ev drivers bc the charge won’t hold, not to mention back up charging stations bc everyone will want to use it. It’s like a quick charger for your phone. Yes it’s fast but the phones battery died three times as fast when charged that way. This is ignorant.

Every car should be a Hybrid so we can make our own decision .