This artist’s rendering shows a night view of the Extremely Large Telescope in operation on Cerro Armazones in northern Chile. The telescope is shown using lasers to create artificial stars high in the atmosphere. The first stone ceremony for the telescope was attended by the President of Chile, Michelle Bachelet Jeria, on 26 May 2017. Credit: ESO/L. Calçada

M1, the primary mirror of ESO’s Extremely Large Telescope (ELT), is the centerpiece of the revolutionary astronomy machine currently under construction in Chile’s Atacama Desert. Too large to be made from a single piece of glass, the 39-meter-diameter mirror will consist of 798 hexagonal segments, each about 5 centimeters thick and measuring 1.4 meters across. Producing 798 segments (plus a few additional pieces) that can work together as a single giant mirror to deliver unprecedented astronomical data is an engineering challenge with milestones worth celebrating.

M1 segments begin their life at SCHOTT in Germany as blanks made of Zerodur©, a glass-ceramic material that has very low thermal expansion. After the casting and machining of the blanks to their approximate shape at SCHOTT, the segments are delivered to Safran Reosc, in France. The first 24 segments are currently at Safran Reosc ready to be polished.

Polishing facility inaugurated in Poitiers

To more efficiently handle the polishing and testing of over 900 M1 segments, Safran Reosc has developed a dedicated ELT polishing facility in Poitiers. It was inaugurated on 4 February by Xavier Barcons, ESO Director General, and Martin Sion, Chief Executive Officer of Safran Electronics & Defense. The facility, assembled in a building that used to store aircraft engines, is unique in the world. It has an area of around 5000 square meters (more than 19 times the area of a tennis court) and is furnished with high-tech optics equipment, which is now ready for the mass production of ELT M1 segments. At peak production, Safran Reosc will be completing one mirror segment per day on average.

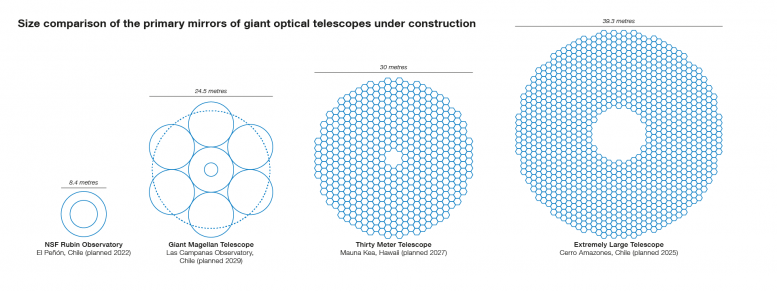

This infographic compares the size of the Extremely Large Telescope’s (ELT) main mirror with that of other planned major optical ground-based telescopes. The ELT, with a main mirror 39 meters in diameter, will be the largest telescope of its kind in the world. This picture was inspired by infographic made by Wikipedia Author Cmglee. Credit: ESO

At this facility, each M1 segment blank — still round in shape — goes through a grinding and polishing process to remove any marks on its surface and level it to an accuracy of a few tens of nanometers. Engineers then cut the segment into a hexagonal shape before the final and most precise polishing stage: ion-beam finishing.

Segment supports delivered

Before this final stage of polishing, segment supports are attached to the mirror segments. These important components will form the backbone structure of the ELT’s primary mirror, providing rigid and adjustable support for each of its 798 segments. Each segment, weighing 250 kg with its support, will later be mounted on three position actuators that can tip and tilt it with incredible accuracy.

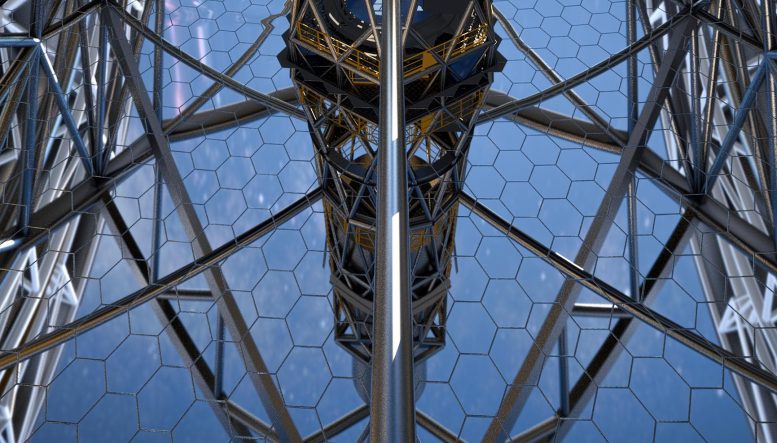

This artist’s rendering of the ELT primary mirror is based on the detailed construction design for the telescope. Credit: ESO/L. Calçada/ACe Consortium

The first set of M1 segment supports, which are being produced and tested to high precision by VDL ETG Projects BV in the Netherlands, has just been delivered to Safran Reosc in Poitiers. The supports will be installed on the back of each segment, which will then be ready for the final polishing stage. Here, an ion beam levels the segment to molecule-sized precision, ironing out any imperfections caused by cutting the hexagonal shape and attaching the support.

ELT Technical Facility nears completion

After polishing and testing, the segments will be ready to begin their journey to Chile. ESO will ship the segments, with their attached supports, in batches in dedicated temperature-controlled containers. Once in Chile, they will be transported to ESO’s Paranal Observatory, in the Atacama Desert, where they will be received in the ELT Technical Facility, which is nearing completion. The giant facility, built on a 6500-square-meter parcel of land, was designed and constructed by Abengoa Chile.

More than just a facility for M1 segments, it will be used to assemble and prepare various elements of the ELT, including all its mirrors. In the first instance, it will be used for storage and integration and coating of the M1 segments, as well as for the coating of the secondary and tertiary mirrors. Special cranes to handle these mirrors — produced by INAMAR, a Chilean representative of German brand ABUS — were recently installed in the facility.

The next two steps in the life of an ELT M1 mirror segment also happen in this high-tech facility. To ensure the segments are aligned as desired once they are installed on the telescope, edge sensors are fixed on each segment. Finally, the segments are sent to the M1 coating plant, designed and manufactured by AGC Glass Europe, at the ELT Technical Facility. There, the segments are covered with a thin layer of silver and a protective coating. They are then ready to make their last journey to Cerro Armazones, the mountain that hosts the ELT, for installation on the telescope.

New contract signed for washing and stripping of M1 segments

Once the ELT starts operating, the facility will be the main hub for the maintenance of ELT’s optical components, including the recoating of M1 segments. Before they are recoated, at a rate of two per day, the segments have to be stripped of their old coating and washed. Last month, a contract with Swedish firm Fagerstroem Industrikonsult AB for the M1 washing and stripping plant entered into force. Segments going through this plant are subjected to a ‘chemical etching’ process, specially developed for ESO by the Danish company IPU, to remove the old coating from the surface. Each M1 segment is then carefully washed and dried before going through a cleaning control to ensure its surface is ready to receive a new coating.

Once a segment is recoated, it is ready to be taken up the mountain for reinstallation on ESO’s ELT. There, it will continue its role of working together with the other segments as a single huge mirror helping to fulfill ELT’s mission to tackle the biggest astronomical challenges of our time.

Be the first to comment on "Incredible Journey of Main Mirror Segments for the Extremely Large Telescope"