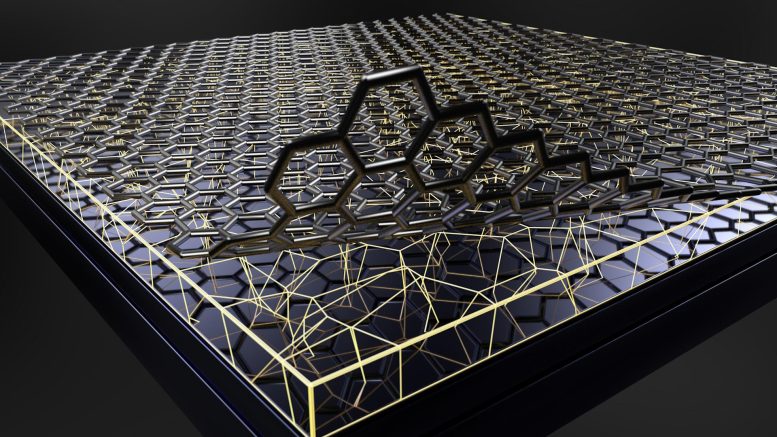

Scientists applied a simple approach for growing hBN films on the surface of ubiquitous steels and other metal alloys to “armor” them and thus increase their capabilities. Credit: Adam Malin/ORNL, U.S. Dept. of Energy

Hexagonal boron nitride coatings on metal alloys enhance durability, reduce friction, and protect against harsh conditions, paving the way for improvements in solar panels, semiconductors, and aerospace components.

Researchers demonstrated that stainless steel and other metal alloys coated with hexagonal boron nitride, or hBN, exhibit non-stick or low-friction qualities along with improved long-term protection against harsh corrosion and high-temperature oxidation in air.

Metal alloys — mixtures of two or more metals — are created to be strong, durable, and resistant to corrosion or oxidation. By adding coatings, or “armor,” to make those materials even tougher, scientists could enhance existing products and enable the creation of new, innovative ones.

Applications of Armored Metal Alloys

For example, armoring may boost the ability of solar panels to conduct heat and resist environmental factors. Additionally, it allows semiconductors to maintain proper operating temperature, and aerospace turbine blades to guard against wear, reduce friction and withstand hot conditions.

Innovative Coating Process

The hBN coatings are produced from a combination of solid boron sources and molecular nitrogen by using a process called atmospheric pressure chemical vapor deposition.

“This synthesis technique addresses scalability issues such as cost and process safety in applications where those aspects have been problematic,” said ORNL’s Ivan Vlassiouk, who led the study. “Besides providing a versatile protective layer for steels and metals, using this process to synthesize single- and few-layer hBN for emerging two-dimensional electronic and photonic devices could improve their performance.”

Reference: “Armor for Steel: Facile Synthesis of Hexagonal Boron Nitride Films on Various Substrates” by Ivan Vlassiouk, Sergei Smirnov, Alexander Puretzky, Olugbenga Olunloyo, David B. Geohegan, Ondrej Dyck, Andrew R. Lupini, Raymond R. Unocic, Harry M. Meyer, Kai Xiao, Dayrl Briggs, Nickolay Lavrik, Jong Keum, Ercan Cakmak, Sumner B. Harris, Marti Checa, Liam Collins, John Lasseter, Reece Emery, John Rayle, Philip D. Rack, Yijing Stehle, Pavan Chaturvedi, Piran R. Kidambi, Gong Gu and Ilia Ivanov, 20 October 2023, Advanced Materials Interfaces.

DOI: 10.1002/admi.202300704

You’re article on hexagonal metal coating. How about engine cylinders? Let’s coat some engine cylinders

The engine would need space to do such a thing.

Woodworking machine surfaces are eagerly waiting to become permanently low friction. HMC? Nedox? Is there any technology ready or imminent?

Well, it seems we need to then snare us an intact Chinese Spy Balloon, repurpose/replace the tech inside, coat the thing with several layers Hex Boron Nitride, & then send that mf into Venus’ atmosphere around ~50Km up. Then we just observe — how long will it last? We could even hand over the marketing to the PowerBall Multi-State Alliance for people to bet a dollar on every week. The time noted for when contact is lost, the person that guessed it gets the jackpot. It’d probably be the first space project to turn a profit the fastest in the history of space travel!

Boron nitride coatings have been used on premium AR 15 bolt carrier groups for a long time. Welcome to the 21st century, everyone else.

seems like alot of people have ideas for the coating.. who has funding for the equipment? I have experience with vapor deposition processes. let’s go