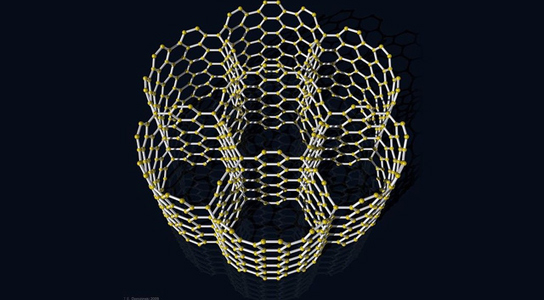

Scientists have developed new methods for making higher-performance computer chips using carbon nanotubes. Credit: Image by TED-43 under Creative Commons license

Scientists have developed new methods that could result in the production of higher-performance computer chips made from tiny straws of carbon nanotubes. It’s been known for a long time that these nanotubes have electronic properties superior to current silicon-based devices.

The scientists published their findings in the journal Nature Nanotechnology. In the past, difficulties of manipulating nanotubes have hampered the development of nanotube-chips. In this new experiment, scientists report that a kind of two-part epoxy could place individual nanotubes at high densities.

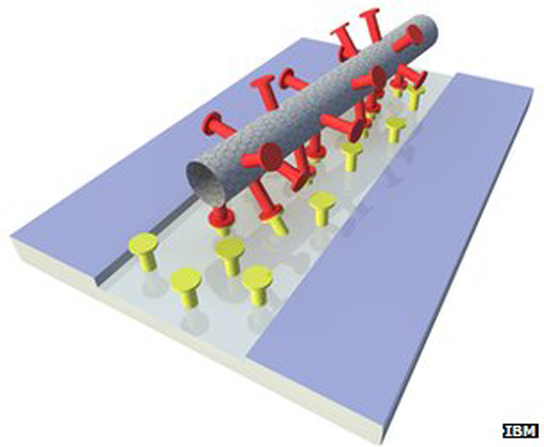

The two molecules on the chip and nanotube work like a two-part epoxy.

The race to replace the current silicon-based technology is on in the semiconductor chip industry. This would allow the development of smaller and faster devices, which place a burden on the physical limit on how small silicon devices can be. There are few realistic successors to silicon’s throne, states James Hannon, materials scientist and co-author of the study.

These units need to be put into production on a 10 or 15 year time scale, so the kinks need to be worked out in the next few years. Right now there has been very few electronic devices produced that can actually outperform silicon.

The main problem was integration, specifically getting billions of nanotubes placed onto a chip with high precision. Current chips use lithography, which uses large wafers of silicon layered with other materials of different electronic properties. The devices are etched onto them, using a focused beam of electrons or charged atoms.

The solution involved a two-step process. First they used a chemical that coats the nanotubes and that makes them soluble in water. Then, they used a solution that binds to the first chemical and the element hafnium, but not silicon. Standard techniques were used to etch patterns in hafnium deposited onto silicon. The chips were double-dipped into the two solutions. One chemical stuck to the hafnium, and the other acted as the second part of a two-part epoxy, tightly binding the nanotubes to the hafnium regions on the chip but not the silicon.

The process resulted in a series of neatly aligned nanotube devices, already wired up within the pattern, at a density of a billion per square centimeter. That’s not good enough to make a microprocessor yet, but it’s only a factor of 10 away, states Hannon. Before, it was a factor of 100.

The etching process needs to be improved and the selection of the right nanotubes of the right length needs to be more efficient. The models suggest a 10-fold jump in performance where the chip runs at more than three times the frequency and consumes a third of the energy.

Reference: “High-density integration of carbon nanotubes via chemical self-assembly” by Hongsik Park, Ali Afzali, Shu-Jen Han, George S. Tulevski, Aaron D. Franklin, Jerry Tersoff, James B. Hannon and Wilfried Haensch, 28 October 2012, Nature Nanotechnology.

DOI: 10.1038/nnano.2012.189

Be the first to comment on "Scientists Work on Developing Computer Chips Made From Nanotubes"