To advance automobile decarbonization, a research team at Osaka Metropolitan University analyzed how alloy elements like titanium improve steel’s performance by optimizing bonding processes, contributing to lighter, more durable electric motors.

Calculations explore how twelve metals, including titanium, form bonds with nitrogen or carbon.

Decarbonizing automobiles involves transitioning from gasoline engines to electric motors and incorporating high-quality steel components that reduce vehicle weight while ensuring efficient motor operation. High-performance steel materials can enhance the quietness of rides and withstand the wear from high-speed motor rotations. Optimizing the steel modification process, which involves enriching the surface with carbon, nitrogen, and alloy elements, is crucial for producing these advanced materials.

To understand the interactions between elements in steel, a systematic investigation has been conducted by an Osaka Metropolitan University research group led by Associate Professor Tokuteru Uesugi of the Graduate School of Informatics. The group theoretically calculated 120 combinations of how 12 alloy elements, including aluminum and titanium, interact with carbon during carburization and nitrogen in the nitriding process.

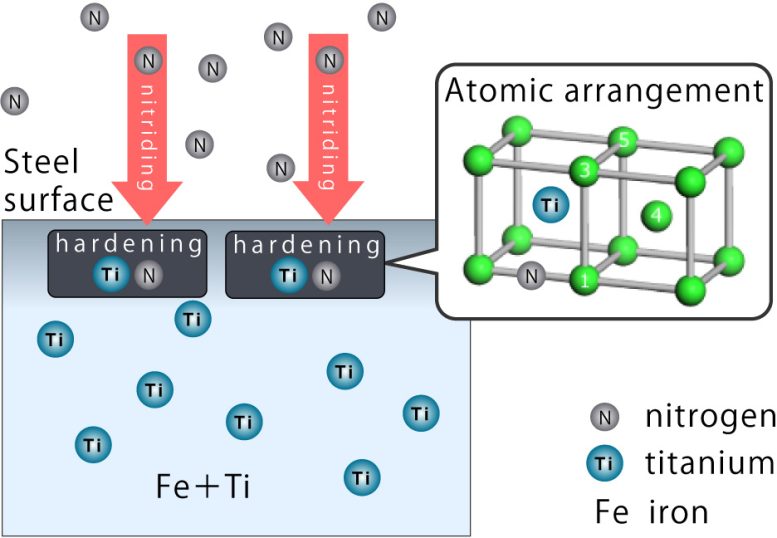

Model of the stable configuration of nitrogen and titanium in steel of iron-titanium alloy. Credit: Osaka Metropolitan University

The results showed that when titanium is placed in a specific arrangement, it bonds with nitrogen or carbon, hardening the iron. The group’s analytical data also showed that the alloy element must have a larger metallic radius than the iron atom to bond well.

“Although it was not easy to elucidate the mechanism from the results of numerous calculations, we used multiple linear regression and stratified analysis through trial and error,” Professor Uesugi stated. “These results are expected to contribute to a better understanding of the mechanisms of steel strengthening and improved durability, and to the development of superior materials.”

Reference: “Interactions between Interstitial and Substitutional Elements of Solute Diatomic and Triatomic Clusters in α-Fe from First-principles Calculations” by Tokuteru Uesugi , Shuji Ashino, Yorinobu Takigawa and Kenji Higashi, 2024, ISIJ International.

DOI: 10.2355/isijinternational.ISIJINT-2024-062

Funding: MEXT Program: Data Creation and Utilization Type Material Research and Development Project, ISIJ Research Promotion Grant, Japan Society for the Promotion of Science, Light Metal Educational Foundation, Japan Science and Technology Agency

Heavy industry, construction, agriculture and international sea and air transport each do an order of magnitude more damage then personal internal combustion vehicles. But yeah… let’s target those anyway and replace them with the scammy electric toys that look clean but in reality cause even more damage to the environment.