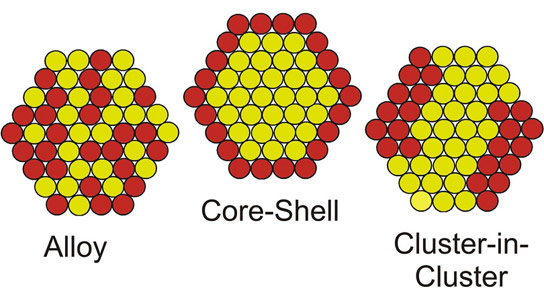

A schematic shows different nanoparticle configurations possible with a new technique to create custom bimetallic nanoparticles. Credit: Argonne National Laboratory

Researchers from the Argonne National Laboratory have developed a new technique for creating nanoalloys.

Argonne, Illinois – Since the dawn of the Bronze Age, people have appreciated the advantages of using alloys rather than single metals to make better materials. Recently, scientists have discovered a recipe for making tiny two-metal structures that could similarly expand the forefront of materials science.

Bimetallic nanoparticles – tiny grains a few dozen to hundreds of atoms in size – hold tremendous promise as catalysts for a number of different applications, according to Jeffrey Elam, a chemist at the U.S. Department of Energy’s Argonne National Laboratory. However, until now researchers lacked a precise and flexible general method for creating them.

According to Elam, traditional methods lack the precision to make a batch of purely bimetallic nanoparticles. Instead, they produce a mixture of both bimetallic and monometallic nanoparticles, and these different nanoparticles have different chemical properties.

According to Elam, there are two major types of bimetallic nanoparticles that scientists try to engineer. In one configuration, called core-shell, one metal completely surrounds the other, like the candy coating over the chocolate center of a Tootsie Pop. In the other configuration, called an alloy, the metals are homogenously mixed at the atomic scale, so that atoms of both metals are present on the surface of the nanoparticle.

Theoretical calculations predict that both types of bimetallic nanoparticles can be exceptional catalysts in applications such as biofuels and fuel cells. But scientists have lacked a general strategy to synthesize either type of nanoparticle on any surface and for a broad range of different metals.

In order to overcome these limitations, Elam and his colleagues at Argonne turned to atomic layer deposition (ALD), a technique borrowed from semiconductor manufacturing, in which extremely thin sheets of material are laid on top of each other one at a time. Each time an ALD “cycle” is performed, a new sheet of material just a few atoms thick is deposited. ALD had been used in the past to create a variety of materials with customizable chemical and electrical properties, but until now researchers had not been able to selectively grow bimetallic nanoparticles with enough control to create successful catalysts.

ALD has been used previously to grow single-metal nanoparticles on surfaces, but the Argonne breakthrough lets scientists grow the second metal only on the first metal, and not on the surrounding surfaces. The keys involved carefully controlling the growth temperature and judicious selection of the chemicals used. Using this strategy, the Argonne researchers were able to make both core-shell and alloy nanoparticles while controlling the particle composition and particle size on a variety of different surfaces.

“It’s like being able to customize a car with the exact features you want it to have,” Elam said. “Once we’ve created these custom nanoparticle catalysts, we can pass them on to our scientific colleagues for a test drive.”

This study was organized by the Institute for Atom-efficient Chemical Transformations (IACT), an Energy Frontier Research Center funded by the DOE’s Office of Science. Founded in 2009 as a five-year program, IACT partnered Argonne with Brookhaven National Laboratory, Northwestern University, Purdue University, and the University of Wisconsin at Madison to improve the efficiency of conversion of biomass feedstocks into combustible fuels.

Be the first to comment on "Argonne Researchers Develop New Technique for Creating Nanoalloys"