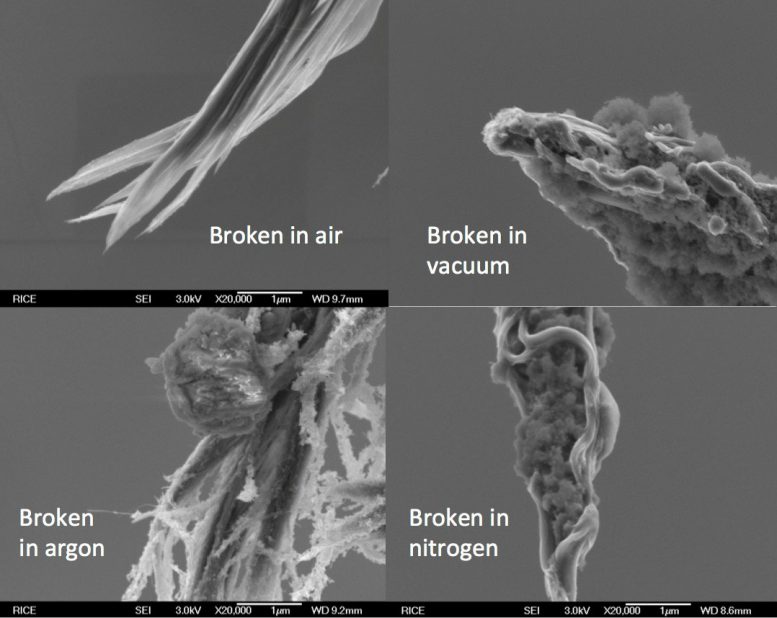

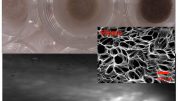

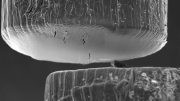

Scanning electron microscope images show typical carbon nanotube fibers created at Rice University and broken into two by high-current-induced Joule heating. Rice researchers broke the fibers in different conditions – air, argon, nitrogen and a vacuum – to see how well they handled high current. The fibers proved overall to be better at carrying electrical current than copper cables of the same mass. Credit: Kono Lab/Rice University

A new study from Rice University shows that carbon nanotube fibers have a greater capacity to carry electrical current than traditional copper cables of the same mass.

On a pound-per-pound basis, carbon nanotube-based fibers invented at Rice University have a greater capacity to carry electrical current than copper cables of the same mass, according to new research.

While individual nanotubes are capable of transmitting nearly 1,000 times more current than copper, the same tubes coalesced into a fiber using other technologies fail long before reaching that capacity.

But a series of tests at Rice showed the wet-spun carbon nanotube fiber still handily beat copper, carrying up to four times as much current as a copper wire of the same mass.

That, said the researchers, makes nanotube-based cables an ideal platform for lightweight power transmission in systems where weight is a significant factor, like aerospace applications.

Scientists have created the first pure carbon nanotube fibers that combine many of the best features of highly conductive metal wires, strong carbon fibers and pliable textile thread.

The analysis led by Rice professors Junichiro Kono and Matteo Pasquali appeared online this week in the journal Advanced Functional Materials. Just a year ago the journal Science reported that Pasquali’s lab, in collaboration with scientists at the Dutch firm Teijin Aramid, created a very strong conductive fiber out of carbon nanotubes.

Present-day transmission cables made of copper or aluminum are heavy because their low tensile strength requires steel-core reinforcement.

Scientists working with nanoscale materials have long thought there’s a better way to move electricity from here to there. Certain types of carbon nanotubes can carry far more electricity than copper. The ideal cable would be made of long metallic “armchair” nanotubes that would transmit current over great distances with negligible loss, but such a cable is not feasible because it’s not yet possible to manufacture pure armchairs in bulk, Pasquali said.

In the meantime, the Pasquali lab has created a method to spin fiber from a mix of nanotube types that still outperforms copper. The cable developed by Pasquali and Teijin Aramid is strong and flexible even though at 20 microns wide, it’s thinner than a human hair.

Pasquali turned to Kono and his colleagues, including lead author Xuan Wang, a postdoctoral researcher at Rice, to quantify the fiber’s capabilities.

Pasquali said there has been a disconnect between electrical engineers who study the current carrying capacity of conductors and materials scientists working on carbon nanotubes. “That has generated some confusion in the literature over the right comparisons to make,” he said. “Jun and Xuan really got to the bottom of how to do these measurements well and compare apples to apples.”

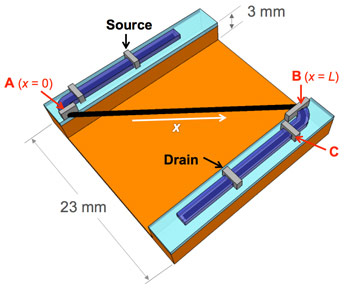

The researchers analyzed the fiber’s “current carrying capacity” (CCC), or ampacity, with a custom rig that allowed them to test it alongside metal cables of the same diameter. The cables were tested while they were suspended in the open air, in a vacuum, and in nitrogen or argon environments.

Electric cables heat up because of resistance. When the current load exceeds the cable’s safe capacity, they get too hot and break. The researchers found nanotube fibers exposed to nitrogen performed best, followed by argon and open air, all of which were able to cool through convection. The same nanotube fibers in a vacuum could only cool by radiation and had the lowest CCC.

“The outcome is that these fibers have the highest CCC ever reported for any carbon-based fibers,” Kono said. “Copper still has better resistivity by an order of magnitude, but we have the advantage that carbon fiber is light. So if you divide the CCC by the mass, we win.”

Kono plans to further investigate and explore the fiber’s multifunctional aspects, including flexible optoelectronic device applications.

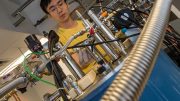

A test rig designed by the Kono Lab at Rice allowed nanofiber and copper cables of equivalent mass to be compared. Credit: Kono Lab

Pasquali suggested the thread-like fibers are light enough to deliver power to aerial vehicles. “Suppose you want to power an unmanned aerial vehicle from the ground,” he mused. “You could make it like a kite, with power supplied by our fibers. I wish Ben Franklin were here to see that!”

The paper’s co-authors are Rice alumnus Natnael Behabtu and graduate students Colin Young and Dmitri Tsentalovich. Kono is a professor of electrical and computer engineering, of physics and astronomy, and of materials science and nanoengineering. Pasquali is a professor of chemical and biomolecular engineering, chemistry, materials science, and nanoengineering. Tsentalovich, Kono, and Pasquali are members of the Richard E. Smalley Institute for Nanoscale Science and Technology.

The research was supported by the Department of Energy, the National Science Foundation, the Robert A. Welch Foundation, Teijin Aramid BV, the Air Force Office of Scientific Research, and the Department of Defense National Defense Science and Engineering Graduate Fellowship.

Reference: “High-Ampacity Power Cables of Tightly-Packed and Aligned Carbon Nanotubes” by Xuan Wang, Natnael Behabtu, Colin C. Young, Dmitri E. Tsentalovich, Matteo Pasquali and Junichiro Kono, 13 February 2014, Advanced Functional Materials.

DOI: 10.1002/adfm.201303865

Be the first to comment on "Carbon Nanotube Fibers Outperform Traditional Copper Cables"