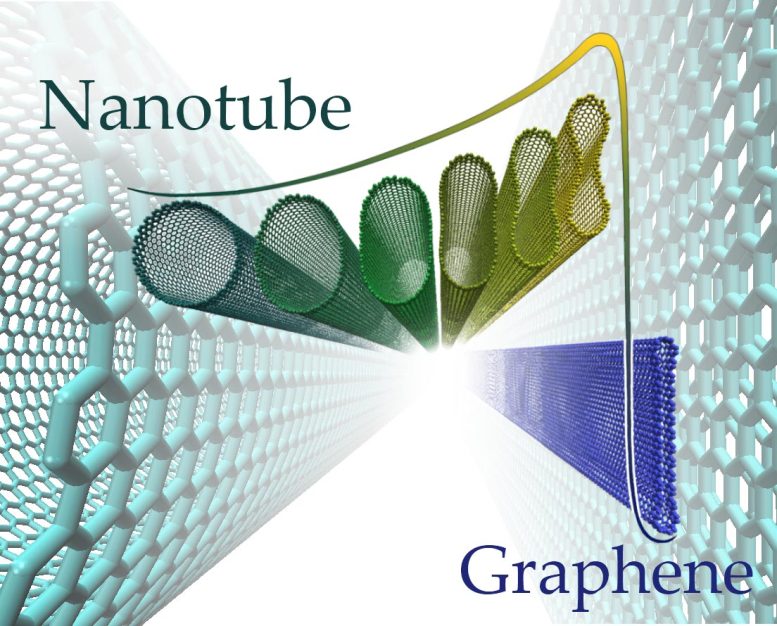

Researchers at Rice University found that nanotubes of a large diameter can spontaneously collapse into closed-edge graphene nanoribbons when atoms on the inside wall get close enough to attract each other. Credit: Ksenia Bets/Rice University

A newly published paper from Rice University researchers details facts and figures about “closed-edge graphene nanoribbons,” carbon nanotubes that appear to collapse during the growth process and have properties of both nanotubes and graphene nanoribbons.

Researchers at Rice’s Richard E. Smalley Institute for Nanoscale Science and Technology have come up with a set of facts and figures about carbon nanotubes that appear to collapse during the growth process; they found that these unique configurations have properties of both nanotubes and graphene nanoribbons.

What the researchers call “closed-edge graphene nanoribbons” could kick-start research into their usefulness in electronics and materials applications.

The pioneering work led by Robert Hauge, a distinguished faculty fellow in chemistry at Rice, is detailed in a paper that appeared online this month in the American Chemical Society journal ACS Nano.

“A collapsed nanotube looks a lot like graphene in the middle, but exactly like buckyballs (carbon-60 molecules, a Nobel Prize-winning discovery at Rice) on the sides,” Hauge said. “That means you have the chemistry of graphene in the middle and the chemistry of buckyballs on the edges. And you can separate the two electronically by putting functional groups on the sides to isolate the top and bottom layers.

“If you do edge chemistry that turns the sides into insulators, then the top doesn’t communicate with the bottom electronically, except through some van der Waals-type or excited-state interaction,” he said. “That’s where the new physics and perhaps electronic properties will come from.”

The finding may lead to grown-to-order, two- or four-layer graphene nanoribbons with perfect edges, a product difficult to attain by unzipping or otherwise slicing nanotubes. “The graphene world is searching for ways to make well-defined ribbons,” Hauge said. “They always have to cut up graphene and end up with ill-defined sides that affect their electronic properties. These have the advantage of a much better-defined edge.”

Hauge’s awareness of earlier work on nanotube collapse led him to study the phenomenon. “I’ve been interested in growing larger diameter nanotubes, based on catalyst particle size, for some time now,” he said. “We thought they could collapse, so we started looking for the evidence.”

The team found that folds, twists, and kinks in nanotubes seen through a transmission electron microscope and measured through an atomic force microscope were good indicators of collapsed nanotubes. These nanotubes were about 0.7 nanometers in height along the middle and a little more at what the researchers called the “highly strained bulbs” at the edges. But finding flattened tubes didn’t indicate how they got that way.

Hauge approached Rice theoretical physicist Boris Yakobson to see how the intrinsic energy of atoms in graphene – one of his specialties – would allow such a collapse to happen. Yakobson put graduate student and co-author Ksenia Bets on the case.

“Originally, we thought this would be a small and simple problem, and it turned out to be simple – but not that small,” Bets said. Using molecular dynamic simulation, she fit data from the experimentalists to atomistic models of single-wall nanotubes. “And then, using the same parameters, I produced results for double walls, and they also fit exactly with the experimental data.”

The results gathered over six months confirmed the probability that at growth temperature – 750 degrees Celsius (1,380 degrees Fahrenheit) – flexible nanotubes fluttering in the gas breeze inside a furnace could indeed be induced to collapse. If two atoms on either side of the inner wall get close enough to each other, they can start a van der Walls cascade that flattens the nanotube, Bets said.

“At first, it takes energy to press the nanotube, but you reach a point where the two sides begin to feel each other, and they begin to gain the energy of attraction,” Hauge said. “The van der Waals force takes over, and the tubes then prefer to be collapsed.”

He said the energy required to collapse a nanotube decreases as the tube’s diameter increases. “It’s like a straw,” he said. “For a single-wall nanotube, the bigger it gets, the easier it is to distort.”

More significant were calculations that determined the specific diameters at which nanotubes become prone to collapse. There’s a point, Hauge said, at which a nanotube could go either way, so the dispersion of nanotubes to nanoribbons in a batch of a particular diameter should be about equal. As the diameter increases, the balance shifts in the ribbons’ favor.

“It’s a playoff between the strain energy on the edges versus the van der Walls interaction in the center,” he said. Specifically, they found that freestanding single-wall tubes become amenable to collapse when they are at least 2.6 nanometers in diameter — what the researchers called the “energy equivalence point.” Theory dictates that diameter would drop to 1.9 nanometers for a single-wall tube sitting on a graphene surface, he said, because of additional atomic interaction with the substrate.

Double-wall nanotubes reach energy equivalence at 4 nanometers, Hauge said, but nanotubes with more walls would take much more – probably too much – energy to collapse.

Bets’ formulas agreed nicely with his group’s observations, Hauge said. “What we measured in this paper for the first time is the point where the energy of a collapsed tube is equal to that of an uncollapsed tube,” he said. “That’s the tipping point. Anything above, energetically, prefers to be collapsed rather than uncollapsed. It’s a fundamental property of nanotubes that hadn’t been measured before.”

The discovery has implications for bundles of nanotubes beginning to see use in fibers for electrical applications or as strengthening elements in advanced materials. “The question is whether a layer of collapsed tubes in a bundle is actually more energetically favorable than that same bundle of hexagonally shaped tubes,” Hauge said. “That hasn’t been determined.”

Many basic questions remain, Hauge said. The researchers don’t know whether a nanotube collapses along its entire length, nor whether pressure from outside could start a chain reaction leading to collapse. “It’s possible that you could apply pressure to force everything to collapse, and it would stay that way because that’s what it wants to be,” he said. They would also like to know whether a nanotube’s chirality – its internal arrangement of atoms – influences collapsing.

But he believes nano researchers will have a field day with the possibilities. “This should get people thinking about the whole area of larger-diameter nanotubes and what they might offer,” he said. “It’s like what that guy on the radio used to say: We’ve all heard the story of nanotubes – and now we know the rest of the story.”

Reference: “Closed-Edged Graphene Nanoribbons from Large-Diameter Collapsed Nanotubes” by Chenguang Zhang, Ksenia Bets, Seung Soo Lee, Zhengzong Sun, Francesca Mirri, Vicki L. Colvin, Boris I. Yakobson, James M. Tour and Robert H. Hauge, 7 June 2012, ACS Nano.

DOI: 10.1021/nn301039v

Lead author of the paper is Chenguang Zhang, a visiting student at Rice also affiliated with Tianjin University. Co-authors with Hauge, Yakobson and Bets include former graduate student Zhengzong Sun; graduate students Seung Soo Lee and Francesca Mirri; Vicki Colvin, Rice’s vice provost for research, the Kenneth S. Pitzer-Schlumberger Professor of Chemistry, and a professor of chemical and biomolecular engineering; and James Tour, the T.T. and W.F. Chao Chair in Chemistry as well as a professor of mechanical engineering and materials science and of computer science. Yakobson is the Karl F. Hasselmann Chair in Engineering and a professor of materials science and mechanical engineering and of chemistry.

The research was supported by Lockheed Martin, the National Science Foundation, the Office of Naval Research MURI program, and the Air Force Research Laboratory, with partial support from the China Scholarship Council.

Be the first to comment on "“Closed-Edge Graphene Nanoribbons”"