Liquid hydrogen requires a larger tank volume than today’s aviation kerosene but is at the same time lighter and contains more energy per kilogram of fuel. Credit: Cranfield University

By 2045, nearly all short-range flights could be hydrogen-powered, with significant advancements in technology driving efficiency and range. Sweden may start hydrogen flights by 2028, aiming for major global adoption by 2050.

Hydrogen-powered flight would offer new opportunities for fossil-free travel, and technological advancements in the field are moving fast. New studies from Chalmers University of Technology in Sweden indicate that by 2045, almost all air travel within a 750-mile radius could be made with hydrogen-powered aircraft. Additionally, with a novel heat exchanger currently in development, this range could be even further.

“If everything falls into place, the commercialization of hydrogen flight can go really fast now. As early as 2028, the first commercial hydrogen flights in Sweden could be in the air,” says Tomas Grönstedt, Professor at Chalmers University of Technology, and Director of the competence center TechForH2* at Chalmers.

These technological advances can be seen inside the Chalmers wind tunnels, where researchers test airflow conditions in cutting-edge facilities. Here, more energy-efficient engines are being developed that pave the way for safe and efficient hydrogen flight for heavy-duty vehicles.

Heat exchanger with exhaust gas preheater, developed according to the new concept. Credit: GKN Aerospace

Potential of Hydrogen-Powered Aviation

Short and medium-range hydrogen-powered flights are the closest to being realised. A recently published study from Chalmers shows that hydrogen-powered flights have the potential to meet the needs of 97 percent of all intra-Nordic flight routes and 58 percent of the Nordic passenger volume by 2045.

For this study, the researchers assumed a maximum flight distance of 750 miles and the use of an existing aircraft model adapted for hydrogen power. The study, led by doctoral student Christian Svensson in Grönstedt’s research group, also showcased a new fuel tank that could hold enough fuel, was insulated enough to hold the super-cold liquid hydrogen, and at the same time was lighter than today’s fossil-based fuel tank systems.

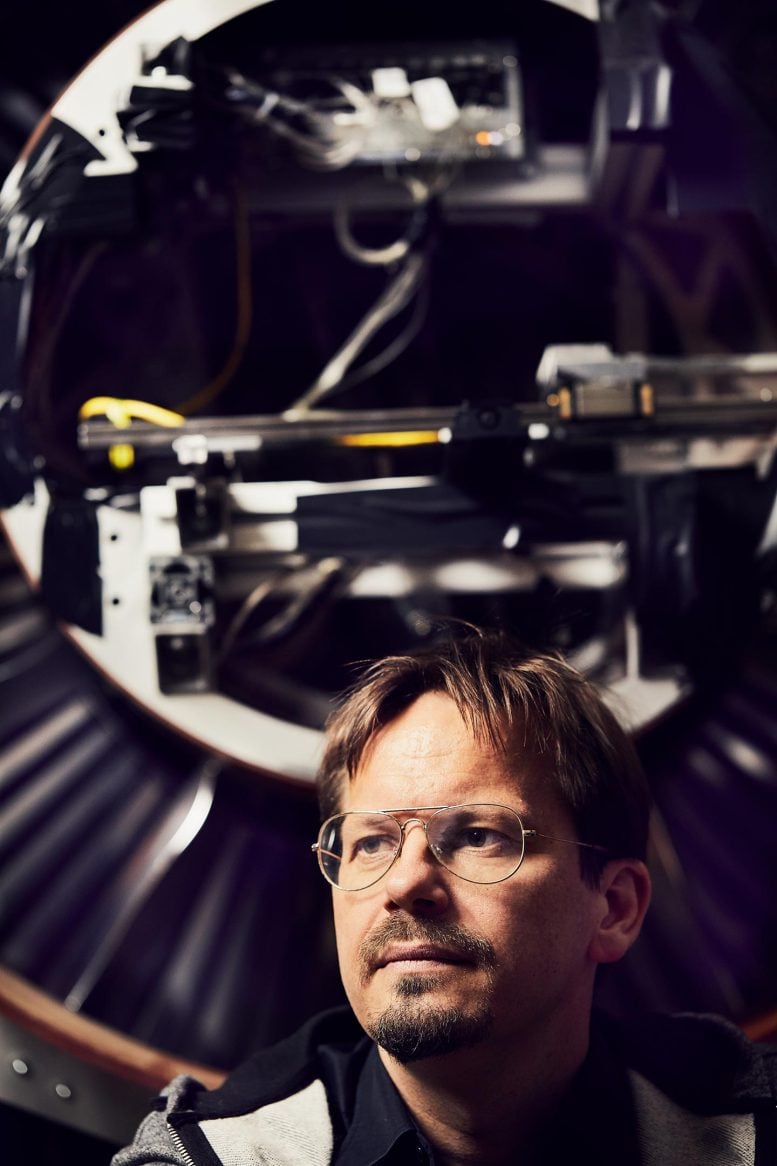

Tomas Grönstedt, Professor at Chalmers University of Technology, Sweden, and Director of the competence centre TechForH2. Credit: Chalmers University of Technology | Mia Halleröd Palmgren

Hydrogen and Hydrogen Flight:

- Hydrogen, H2, is an invisible, odorless, volatile gas that liquefies at about -250 degrees Celsius (20 Kelvin).

- If the hydrogen is produced using renewable energy, it is free of carbon dioxide emissions. This is known as ‘green hydrogen’.

- Hydrogen flights can be powered either electrically, using fuel cells that convert the hydrogen into electricity through catalysis, or with jet engines, where the hydrogen is burned in a gas turbine.

- Hydrogen contains more energy per kilogram than today’s kerosene and also has the advantage that the residual product of combustion is mainly water vapor.

- The gas is highly flammable if mixed with air, which is why high-efficiency sensors are necessary.

- In industry, hydrogen is currently used in the production of, for example, fossil-free steel.

Innovative Heat Exchanger Development

Heat exchangers are a vital part of hydrogen aviation, and they are a key part of the technological advancements taking place. To keep the fuel systems lightweight, the hydrogen needs to be in liquid form. This means that the hydrogen is kept supercool in the aircraft, typically around -250 degrees Celsius. By recovering heat from the hot exhausts of the jet engines, and by cooling the engines in strategic locations they become more efficient. To transfer the heat between the supercool hydrogen and the engine, novel types of heat exchangers are needed.

To meet this challenge, researchers at Chalmers have been working for several years to develop a completely new type of heat exchanger. The technology, which is now patent pending by partner GKN Aerospace, takes advantage of hydrogen’s low storage temperature to cool engine parts and then uses waste heat from the exhaust gases to preheat the fuel several hundred degrees before it is injected into the combustion chamber.

Carlos Xisto, Associate Professor, Division of Fluid Mechanics, Department of Mechanics and Maritime Sciences, Chalmers University of Technology. Credit: Sören Håkanlind

“Every degree increase in temperature reduces fuel consumption and increases range. We were able to show that short- and medium-haul aircraft equipped with the new heat exchanger could reduce their fuel consumption by almost eight percent. Considering that an aircraft engine is a mature and well-established technology, it is a very good result from a single component,” says Carlos Xisto, Associate Professor at the Division of Fluid Mechanics at Chalmers, and one of the authors of the study.

The researchers also note that with more optimization, this type of heat exchanger technology in a regular Airbus A320 commercial aircraft could provide an improved range of up to ten percent, or the equivalent of the Gothenburg-Berlin route (approximately 450 miles).

Tomas Grönstedt, Professor at Chalmers University of Technology, Sweden, and Director of the competence center TechForH2. Credit: Chalmers University of Technology | Anna-Lena Lundqvist

Collaborative Efforts and Industry Outlook

The work to develop solutions for hydrogen aviation of the future is taking place on a broad front, with governments, universities and private companies working together. In Sweden, the innovation cluster, Swedish Hydrogen Development Centre (SHDC), brings together key players, including industry leaders and experts from academia. At a recent SHDC seminar, researchers from Chalmers presented their work and several commercial companies testified to major investments in hydrogen flights in the coming years. Whilst the technology is well advanced, the challenges lie rather in the large investments required, and in developing infrastructure, business models and partnerships to be able to produce, transport and store the hydrogen so that the transition to hydrogen flight is possible. A total transition is expected to require around 100 million tonnes of green hydrogen annually.

“There are industry expectations that 30–40 percent of global aviation will be powered by hydrogen by 2050. It is likely that for a number of years to come, we will need a mix of aircraft that run on electricity, less environmentally harmful e-jet fuel and hydrogen. But every aircraft that can be powered by hydrogen from renewable energy reduces carbon dioxide emissions,” says Grönstedt.

Within TechForH2, there are good conditions to take on the hydrogen challenge, and with a budget of SEK 162 million (equivalent USD 15.5 million), the competence centre can contribute to the development of a number of different research areas that link hydrogen and heavy transport.

References:

“Compact heat exchangers for hydrogen-fueled aero engine intercooling and recuperation” by Alexandre Capitao Patrao, Isak Jonsson, Carlos Xisto, Anders Lundbladh and Tomas Grönstedt, 28 January 2024, Applied Thermal Engineering.

DOI: 10.1016/j.applthermaleng.2024.122538

“Hydrogen fuel cell aircraft for the Nordic market” by Christian Svensson, Amir A.M. Oliveira and Tomas Grönstedt, 4 March 2024, International Journal of Hydrogen Energy.

DOI: 10.1016/j.ijhydene.2024.02.382

Funding: Swedish Energy Agency, Horizon 2020 Framework Programme, Swedish Research Council

Be the first to comment on "Flying Clean and Green: Hydrogen Flights Set to Revolutionize Air Travel"