As part of the Artemis program, NASA has a concept for the core surface elements needed to establish a sustained presence on the Moon, which emphasizes mobility to allow astronauts to explore more and conduct more science.

The process of building landing pads, habitats, and roads on the Moon will likely look different than the common construction site on Earth. Excavation robots, for one, will need to be lightweight yet capable of digging in reduced gravity. A large-scale construction system could be autonomous and equipped to work without astronauts’ help.

As part of the Artemis program, NASA has a concept for the core surface elements needed to establish a sustained presence on the Moon, which emphasizes mobility to allow astronauts to explore more and conduct more science. NASA is considering putting in place a lunar terrain vehicle, habitable mobility platform or lunar RV, and surface habitat on the Moon by the end of the decade. The agency is investing in advanced manufacturing – one of five industries of the future to enable space exploration and improve life on Earth – including technologies that could find and use available resources on the Moon and Mars to build out future infrastructure.

Today, NASA is working with ICON, a construction technologies company based in Austin, Texas, on early research and development of a space-based construction system that could support future exploration of the Moon and Mars. The company has 3D printed communities of homes and structures on Earth and participated in NASA’s 3D Printed Habitat Challenge, demonstrating a construction method and technologies that may be adaptable for applications beyond our home planet.

ICON illustration of a conceptual lunar base with 3D printed infrastructure, including landing pads and habitats. Credit: ICON/SEArch+

“To be successful in our future missions, we have to invest in new, cutting-edge technologies today,” said Niki Werkheiser, NASA’s Game Changing Development program executive. The program is part of the agency’s Space Technology Mission Directorate. “Near-term research and development will help ensure we can expand building capabilities on other worlds when the time comes.”

Another U.S. government agency is interested in the technology and its applications here on Earth. The U.S. Air Force awarded ICON a dual-use Small Business Innovation Research (SBIR) contract to expand 3D printing of livable and workable structures. Part of the contract, which NASA contributed funding to, will explore commonalities between Earth-based and off-Earth applications. ICON will also invest in the effort.

“Joining forces and cost-sharing among multiple government agencies allows us to accelerate the development timeline and bring the core capabilities that we have a common interest into fruition sooner,” said Werkheiser. “Together, we will help mature technologies that will have benefits for humanity – on Earth and in space.”

ICON will work with NASA’s Marshall Space Flight Center in Huntsville, Alabama, under the Moon to Mars Planetary Autonomous Construction Technologies (MMPACT) project to test lunar soil simulant with various processing and printing technologies. NASA is partnering with industry, government, and academic institutions under the MMPACT project.

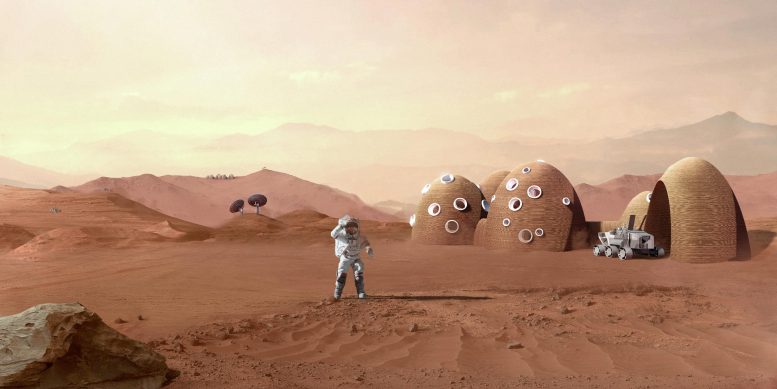

Illustration of a Mars habitat concept developed by the Colorado School of Mines and ICON for NASA’s 3D-Printed Habitat Challenge. Credit: Logan Architecture

“We want to increase the technology readiness level and test systems to prove it would be feasible to develop a large-scale 3D printer that could build infrastructure on the Moon or Mars,” said Corky Clinton, associate director of Marshall’s Science and Technology Office. “The team will use what we learn from the tests with the lunar simulant to design, develop, and demonstrate prototype elements for a full-scale additive construction system.”

Based on the progress, NASA could award ICON additional funding and explore the opportunity of an in-situ test on the lunar surface.

“From the very founding of ICON, we’ve been thinking about off-world construction,” said Jason Ballard, co-founder and CEO of ICON. “I am confident that learning to build on other worlds will also provide the necessary breakthroughs to solve housing challenges we face on this world. These are mutually reinforcing endeavors. Sometimes, for the biggest problems, it becomes necessary to look up at the sky and not only down at our feet.”

The SBIR award will build on ICON’s commercial activities and demonstrations during Phase 3 of NASA’s 3D Printed Habitat Challenge. For the challenge, ICON partnered with the Colorado School of Mines in Golden. The team won a prize for 3D printing a structure sample that adequately held a seal when filled with water.

“It is rewarding to see past NASA challenge competitors go on to work with the government in other ways,” said Amy Kaminski, the program executive for prizes and challenges at NASA. “It shows our approach of reaching out to groups outside of the traditional aerospace sector to solve challenges facing us in space and on Earth can result in unique collaborations to further NASA’s technology development efforts.”

Its an obligation tobexplore to know things cocret and not just theoreticly. But we have a perfect place to treat and to remake it good as it allways was. Planet earth is not less evaluated than our selves. Now we can see how worthless we r. Just look at Earth it”s reflecting our way of existance. Nothing write. We r all wrong and bad as the earth now. Its our behave just look what we have done. So many industry so much factory. Cars airplans ,ships,trains,submarine rockets. Weapons. Buildings with no need or porpuse just for thriving. Hhhh. What a thrive?its=loose and lost