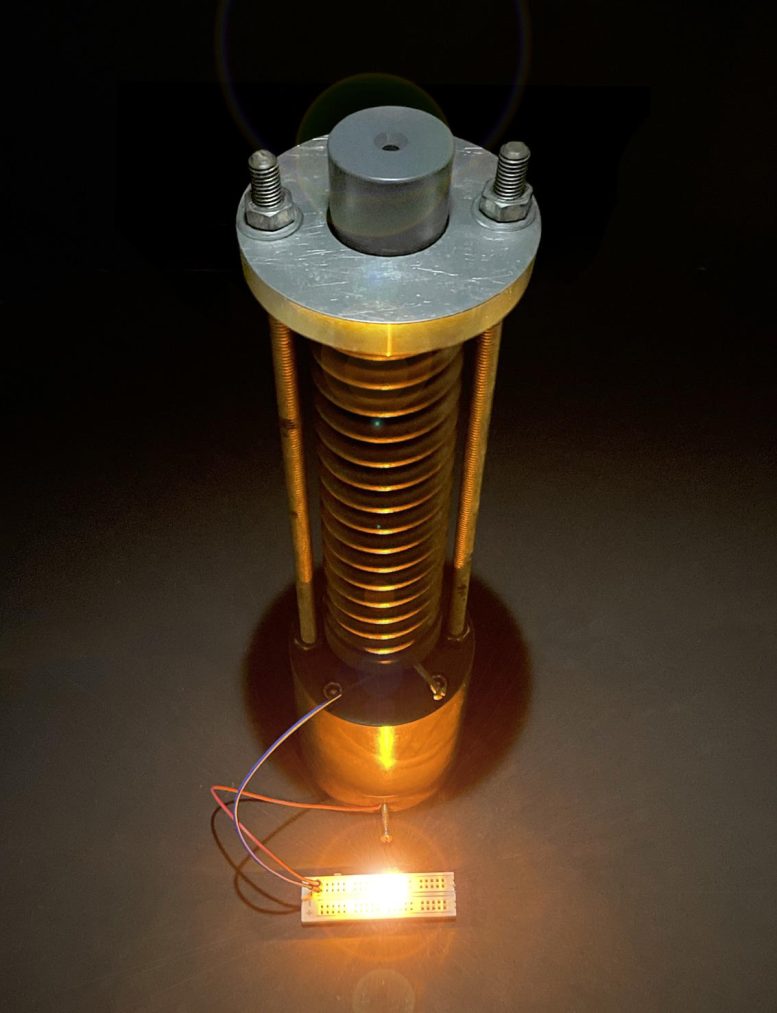

MIT engineers have created a “supercapacitor” made of ancient, abundant materials, that can store large amounts of energy. Made of just cement, water, and carbon black (which resembles powdered charcoal), the device could form the basis for inexpensive systems that store intermittently renewable energy, such as solar or wind energy. Credit: Image courtesy of Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn

Constructed from cement, carbon black, and water, the device holds the potential to offer affordable and scalable energy storage for renewable energy sources.

Two of humanity’s most ubiquitous historical materials, cement and carbon black (which resembles very fine charcoal), may form the basis for a novel, low-cost energy storage system, according to a new study. The technology could facilitate the use of renewable energy sources such as solar, wind, and tidal power by allowing energy networks to remain stable despite fluctuations in renewable energy supply.

The two materials, the researchers found, can be combined with water to make a supercapacitor — an alternative to batteries — that could provide storage of electrical energy. As an example, the MIT researchers who developed the system say that their supercapacitor could eventually be incorporated into the concrete foundation of a house, where it could store a full day’s worth of energy while adding little (or no) to the cost of the foundation and still providing the needed structural strength. The researchers also envision a concrete roadway that could provide contactless recharging for electric cars as they travel over that road.

The simple but innovative technology is described in a recent paper published in the journal PNAS, in a paper by MIT professors Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn, and four others at MIT and at the Wyss Institute.

Capacitors are in principle very simple devices, consisting of two electrically conductive plates immersed in an electrolyte and separated by a membrane. When a voltage is applied across the capacitor, positively charged ions from the electrolyte accumulate on the negatively charged plate, while the positively charged plate accumulates negatively charged ions. Since the membrane in between the plates blocks charged ions from migrating across, this separation of charges creates an electric field between the plates, and the capacitor becomes charged. The two plates can maintain this pair of charges for a long time and then deliver them very quickly when needed. Supercapacitors are simply capacitors that can store exceptionally large charges.

The amount of power a capacitor can store depends on the total surface area of its conductive plates. The key to the new supercapacitors developed by this team comes from a method of producing a cement-based material with an extremely high internal surface area due to a dense, interconnected network of conductive material within its bulk volume. The researchers achieved this by introducing carbon black — which is highly conductive — into a concrete mixture along with cement powder and water, and letting it cure. The water naturally forms a branching network of openings within the structure as it reacts with cement, and the carbon migrates into these spaces to make wire-like structures within the hardened cement.

These structures have a fractal-like structure, with larger branches sprouting smaller branches, and those sprouting even smaller branchlets, and so on, ending up with an extremely large surface area within the confines of a relatively small volume. The material is then soaked in a standard electrolyte material, such as potassium chloride, a kind of salt, which provides the charged particles that accumulate on the carbon structures. Two electrodes made of this material, separated by a thin space or an insulating layer, form a very powerful supercapacitor, the researchers found.

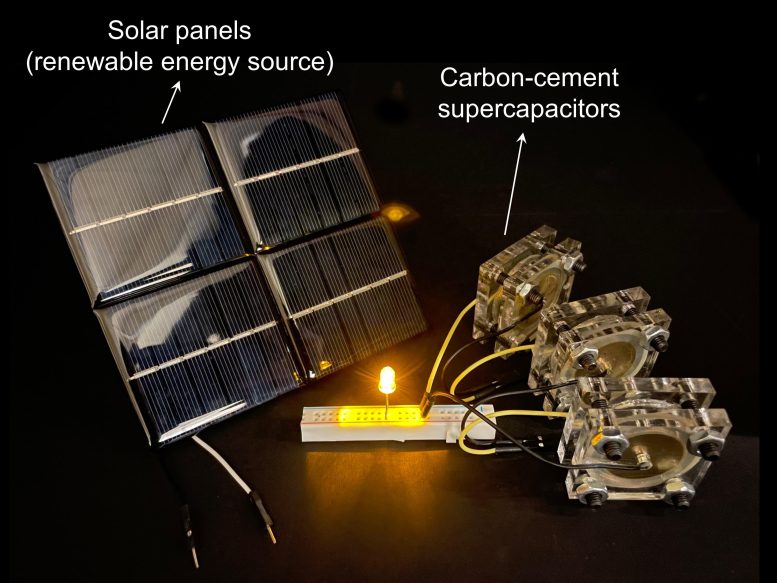

Since the new “supercapacitor” concrete would retain its strength, a house with a foundation made of this material could store a day’s worth of energy produced by solar panels or windmills, and allow it to be used whenever it’s needed. Credit: Image courtesy of Franz-Josef Ulm, Admir Masic, and Yang-Shao Horn

The two plates of the capacitor function just like the two poles of a rechargeable battery of equivalent voltage: When connected to a source of electricity, as with a battery, energy gets stored in the plates, and then when connected to a load, the electrical current flows back out to provide power.

“The material is fascinating,” Masic says, “because you have the most-used manmade material in the world, cement, that is combined with carbon black, that is a well-known historical material — the Dead Sea Scrolls were written with it. You have these at least two-millennia-old materials that when you combine them in a specific manner you come up with a conductive nanocomposite, and that’s when things get really interesting.”

As the mixture sets and cures, he says, “The water is systematically consumed through cement hydration reactions, and this hydration fundamentally affects nanoparticles of carbon because they are hydrophobic (water repelling).” As the mixture evolves, “the carbon black is self-assembling into a connected conductive wire,” he says. The process is easily reproducible, with materials that are inexpensive and readily available anywhere in the world. And the amount of carbon needed is very small — as little as 3 percent by volume of the mix — to achieve a percolated carbon network, Masic says.

Supercapacitors made of this material have great potential to aid in the world’s transition to renewable energy, Ulm says. The principal sources of emissions-free energy, wind, solar, and tidal power, all produce their output at variable times that often do not correspond to the peaks in electricity usage, so ways of storing that power are essential. “There is a huge need for big energy storage,” he says, and existing batteries are too expensive and mostly rely on materials such as lithium, whose supply is limited, so cheaper alternatives are badly needed. “That’s where our technology is extremely promising, because cement is ubiquitous,” Ulm says.

The team calculated that a block of nanocarbon-black-doped concrete that is 45 cubic meters (or yards) in size — equivalent to a cube about 3.5 meters across — would have enough capacity to store about 10 kilowatt-hours of energy, which is considered the average daily electricity usage for a household. Since the concrete would retain its strength, a house with a foundation made of this material could store a day’s worth of energy produced by solar panels or windmills and allow it to be used whenever it’s needed. And, supercapacitors can be charged and discharged much more rapidly than batteries.

After a series of tests used to determine the most effective ratios of cement, carbon black, and water, the team demonstrated the process by making small supercapacitors, about the size of some button-cell batteries, about 1 centimeter across and 1 millimeter thick, that could each be charged to 1 volt, comparable to a 1-volt battery. They then connected three of these to demonstrate their ability to light up a 3-volt light-emitting diode (LED). Having proved the principle, they now plan to build a series of larger versions, starting with ones about the size of a typical 12-volt car battery, then working up to a 45-cubic-meter version to demonstrate its ability to store a house-worth of power.

There is a tradeoff between the storage capacity of the material and its structural strength, they found. By adding more carbon black, the resulting supercapacitor can store more energy, but the concrete is slightly weaker, and this could be useful for applications where the concrete is not playing a structural role or where the full strength-potential of concrete is not required. For applications such as a foundation, or structural elements of the base of a wind turbine, the “sweet spot” is around 10 percent carbon black in the mix, they found.

Another potential application for carbon-cement supercapacitors is for building concrete roadways that could store energy produced by solar panels alongside the road and then deliver that energy to electric vehicles traveling along the road using the same kind of technology used for wirelessly rechargeable phones. A related type of car-recharging system is already being developed by companies in Germany and the Netherlands, but using standard batteries for storage.

Initial uses of the technology might be for isolated homes or buildings or shelters far from grid power, which could be powered by solar panels attached to the cement supercapacitors, the researchers say.

Ulm says that the system is very scalable, as the energy-storage capacity is a direct function of the volume of the electrodes. “You can go from 1-millimeter-thick electrodes to 1-meter-thick electrodes, and by doing so basically you can scale the energy storage capacity from lighting an LED for a few seconds, to powering a whole house,” he says.

Depending on the properties desired for a given application, the system could be tuned by adjusting the mixture. For a vehicle-charging road, very fast charging and discharging rates would be needed, while for powering a home “you have the whole day to charge it up,” so slower-charging material could be used, Ulm says.

“So, it’s really a multifunctional material,” he adds. Besides its ability to store energy in the form of supercapacitors, the same kind of concrete mixture can be used as a heating system, by simply applying electricity to the carbon-laced concrete.

Ulm sees this as “a new way of looking toward the future of concrete as part of the energy transition.”

Reference: “Carbon–cement supercapacitors as a scalable bulk energy storage solution” by Nicolas Chanut, Damian Stefaniuk, James C. Weaver, Yunguang Zhu, Yang Shao-Horn, Admir Masic and Franz-Josef Ulm, 31 July 2023, Proceedings of the National Academy of Sciences.

DOI: 10.1073/pnas.2304318120

The research team also included postdocs Nicolas Chanut and Damian Stefaniuk at MIT’s Department of Civil and Environmental Engineering, James Weaver at the Wyss Institute for Biologically Inspired Engineering, and Yunguang Zhu in MIT’s Department of Mechanical Engineering. The work was supported by the MIT Concrete Sustainability Hub, with sponsorship by the Concrete Advancement Foundation.

Might be great for places like Cape Town, South Africa, which receives an incredibly large number of lightening strikes per year, and now we know how to harvest those lightening strikes with lasers directed into the storm clouds; all that would be needed then would be a very fast variable resistance, so as to be initially a fully open no load circuit thense, once the flow of current is struck; viola! A massive burst of free electricity. I hope they do it.

The energy density is not real good, but the materials are low cost. However they do allude to using more carbon black can store more energy. At some point too much carbon black may cause problems too. It would be interesting to see what the ultimate energy density could be. This might reduce the size of the device down to something manageable. A 1 cubic yard device would be very interesting.

Instead of Carbon Black. How about Graphine?

The concrete would also become heat-conductive via solar energy directly, so using it on roads or bridges would make those surfaces less susceptible to icing in winter.

To me the problem is that even supercapacitors don’t have infinite charge-discharge cycles.

If your house’s foundation/supercapacitor starts to wear out, do you replace your foundation?

For that matter, this is only a ‘solution’ that can be applied to new homes, for all practical solutions.

Oh goodie, more plastic.

As a retired structural designer (not an engineer), I see new articles every week about developments in concrete and new methods and procedures that are very interesting. Recently I have read about replacing some of the sand with the treated, used, coffee grounds and 3-D printing for concrete buildings. These methods could also incorporate this supercapacitor. If the scale for an average house is around a yard each direction, then it could be offset from the existing structure. I’ll be looking for more information on this subject.

Or using coffee grounds in the plaster…that way you can awaken to the fresh smell of coffee every morning,and afternoon, and evening. LOL

“the carbon black is self-assembling into a connected conductive wire.”

I won’t bet on it.

Potassium Chloride is known to damage both the concrete and the reinforcing steel. Seems premature to say no structural concern with this foundation setup.

45m^3 is still large – for instance, a 7x7m patio (23×23 ft) would have to be 3 ft thick to have that volume… And the energy needed to make and ship that amount of concrete is …?

The energy and cost to make and ship is irrelevant, at least in cases where concrete was already going to be used anyway, as in a new housing subdivision, apartment complex, shopping mall (remember those? lol), etc. The vast majority of these materials would be brought on site regardless. *IF* this process proves viable, it would require an addition of a small amount of material and undoubtedly a change in the way the concrete is mixed and poured, which will of course increase the cost somewhat, but likely worth the added benefit. Remains to be seen.

Hey, that looks like the same way the ancient Egyptians did it!

Can be used as a heat source when electricity is applied? Isn’t that what is done to charge these?

I see several issues that need to be resolved before this is practical. One is the fact that cement or concrete have very little exspansive strength and are subject to shrinkage cracking, which I imagine would seriously disrupt the conductivity of the device. Normally concrete shrinkage is controlled by placed reinforing steel bars or remesh steel mats within the material. This still does not completely eliminate this problem and it is not known what effect this will has on the capacitor performance or if alternate reinforcing methods need to be incorporated or the steel would need to be insulated. For a 2000 ft home the concrete would be more than 9″ thick which is more than double the thickness of the average slab. Not an insignificant extra cost. It would be much simpler as a stand alone slab where the concrete could be designed to shrink without being restrained and possibly avoid cracking. The cost is not insignificant either. based on avg concrete prices a 45 cubic meter slab would cost over $5,000 dollars for material and possibly as much for construction. $10,000 for a 10 kw storage system. In comparision a 13.5 kw Tesla powerwall costs $9,200 and $2,000 for installation. It would definitely need to be incorporated into a project as a integral slab to come close to being competative.

Does the Tesla powerwall you used in your example include the batteries and the solar panels? When they talked about using this mixture as a heat source, I wondered why your foundation wouldn’t heat up every time it charged? Would there be something that sends the extra electricity to ground when it reaches capacity? I also thought about how the rebar grid would affect the system. If micro cracks are manageable, maybe fiber mesh would solve that problem,as you mentioned. There are admixtures for concrete, like xypex, that heal cracks by growing crystals across them for water proofing that might take the cracks out of the equation too. I also wonder how they tap the capacitor to use the energy. Would bolting something to the basement wall be like touching an ignition coil and zap you? Still a cool discovery. Hope they make it work.

Hi I hv possible solutions to solve the concerns of potassium chloride entirely and also on many issues as raised by using a green concrete we have developed. M a professional engineer in Spore (humbly my alma mater NUS is 2nd in global ranking to MIT in Civil Engg) and will definitely like to collaborate in this field i undertake what is called frugal innovations. Contact me at liew@strategics. com. sg or WA +6597346228.

Maybe someone should look at every brick home over 100 yrs old and check the energy storage capacity. Maybe there is an energy storage system already in existence that we don’t yet know how to access.

How much electricity can this device store, and how long can it last???

Cement soaked in an electrolyte material, such as potassium chloride, cannot be reinforced by steel rebar, because it would quickly rust. The vast majority of all cement incorporates steel rebar, without which it would not be suitable for structural purposes. That alone greatly limits the applicability of this approach, even if it has no other problems. And this article fails to even mention this fact. Which indicates that worse might be wrong with it.

Concrete can also be reinforced with fiberglass mesh in many applications. Maybe that would be a use for all the old windmill blades they are burying.

There seems to be confusion about cement and concrete. If I understand the released press articles, it is cement that is used and not concrete. Cement is in effect an adhesive added to sand/ gravel etc.

If used on its own in say the Portland form, it is going to be too weak for great blocks of it.

I see no reference to using reinforcing steel etc. Boo Radley makes sense.

Maybe there are size constraints expansion/ contraction

They do mention concrete several times in the article. Cement is the glue in concrete, the carbon would be an admixture in the mix design. The cement/carbon would permeatethe slab with the sand and rock components would be like filled bubbles in the matrix.

It’s frustrating how these guys – who admittedly seem to have discovered/invented something great – move directly into the far future and ignore the practicalities of the present. Most of the world that is in a position to seriously invest in solar/wind/tidal energy (and nukes!) already have houses and roads which probably won’t be rebuilt anytime soon. Great possibilities for sure, but it’s much more practical for me to think about adding this as a 12x12x?? “shed” in the back. How much will that cost? How much power will that store? How long will that last? Will it wear out like a normal capacitor? And you get to skip all of the obvious questions about the structural integrity of the product. “The possibilities are endless”, but I live in the practicality of the present. Maybe I’m just getting old..

This seems like it would work with metal fiber reinforced concrete.

I use stainless steel fiber at a rate of about 50 lb per cubic yard of concrete to make thin shell shapes.

I want to try this mixture but wonder how to connect the power into the matrix.. would that be as simple as embedding a couple of copper plates for the positive and negative AC currant or some sort of DC Wire loops on opposite sides of the slab?

Any references about that available?

Maybe they could look into using the Roman cement? Formula that self heals cracks? I was reading about that recently. It may require moisture though?