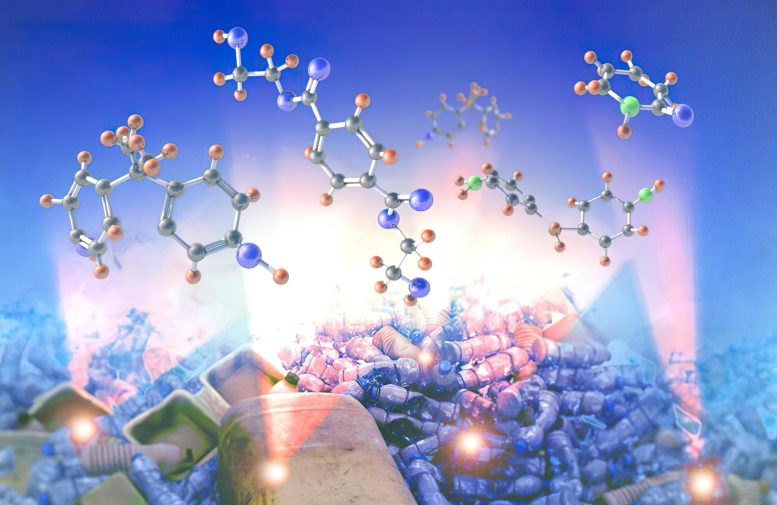

Valuable chemicals are selectively produced from mixed plastic waste by an ORNL-developed plastic deconstruction process. Credit: Tomonori Saito, Md Arifuzzaman and Adam Malin, ORNL/U.S. Dept. of Energy

Mixed plastics can be transformed into useful chemicals.

Nearly 80% of plastic waste ultimately finds its way to landfills or lingers in the environment. Scientists at Oak Ridge National Laboratory have pioneered a method that transforms traditionally unrecyclable mixtures of plastic waste into useful chemicals, offering a new approach in the fight against worldwide plastic pollution.

The technology, invented by ORNL’s Tomonori Saito and former postdoctoral researcher Md Arifuzzaman, uses an exceptionally efficient organocatalyst that allows selective deconstruction of various plastics, including a mixture of diverse consumer plastics. Arifuzzaman, now with Re-Du, is a current Innovation Crossroads fellow.

Production of chemicals from plastic waste requires less energy and releases fewer greenhouse gases than conventional petroleum-based production. Such a pathway provides a critical step toward a net-zero society, the scientists said.

“This concept offers highly efficient and low-carbon chemical recycling of plastics and presents a promising strategy toward establishing closed-loop circularity of plastics,” said Saito, corresponding author of the study published in Materials Horizons.

Reference: “Selective deconstruction of mixed plastics by a tailored organocatalyst” by Md Arifuzzaman, Bobby G. Sumpter, Zoriana Demchuk, Changwoo Do, Mark A. Arnould, Md Anisur Rahman, Peng-Fei Cao, Ilja Popovs, Robert J. Davis, Sheng Dai and Tomonori Saito, 24 July 2023, Materials Horizons.

DOI: 10.1039/D3MH00801K

I’ve seen too many articles like this where they don’t pan out. It’s almost like the plastic industry sends these out themselves, giving us hope that we don’t have to wean ourselves off their products.

Next article, don’t just publish their press release. Give us the details. What chemical byproducts are generated by their process? What happens to these 2nd generation plastic products after they’re used, can they be recycled, or is this just a delay of the inevitable?

Jeff, I completely agree! I read about this 15 years ago, even saw some show about it. But here we are 15 years later, and it’s basically the exact same thing. It’s just another ploy, like the recycling numbers on the bottom of plastic items, that did nothing more than clog up recycling centers. It’s a greedy, disgusting way to inveigle people to keep using plastics.

Perhaps you fellas could follow the link provided to the Materials Horizons referenced article. It’s got all kinds of sciencey names and descriptions and even other papers to quench your thirst for info.