A new study led by the University at Buffalo introduces hydrogen in the fabrication of iron-nitrogen-carbon catalysts, resulting in a significant improvement in both durability and efficiency, nearing platinum’s performance in fuel cells.

Researchers have discovered that adding hydrogen to iron-nitrogen-carbon catalysts could significantly lower the costs of climate-friendly fuel cells.

Researchers have been working tirelessly for many years to find cost-effective alternatives to platinum and other high-priced metals for use in fuel cells. Their efforts have focused on exploring various combinations of three readily available and less expensive materials: iron, nitrogen, and carbon.

However, the journey has been challenging, as achieving a balance between durability and efficiency in these iron-nitrogen-carbon catalysts has proven difficult. While they have been successful in making the catalyst either long-lasting or high-performing, accomplishing both attributes simultaneously remains a significant hurdle.

A new University at Buffalo-led study may offer a solution. In the journal Nature Catalysis, researchers report how adding hydrogen to the fabricating process creates a strong and effective catalyst that approaches the performance of platinum.

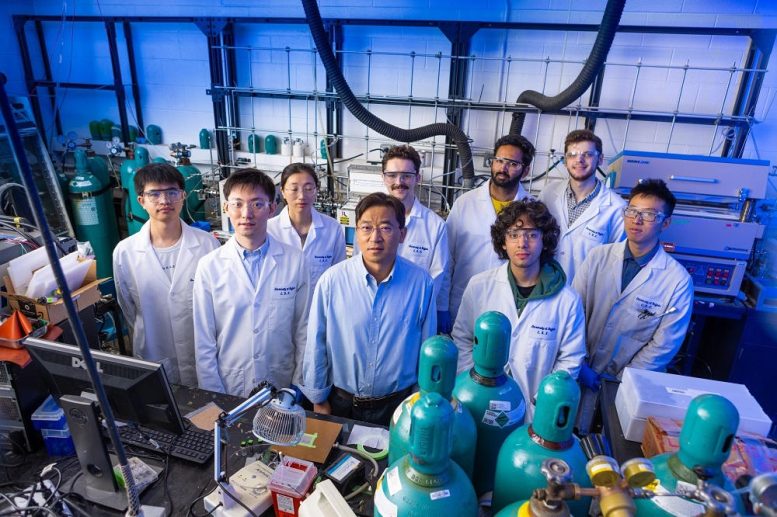

Gang Wu, front and center, is working toward reducing the costs associated with producing climate-friendly fuel cells. Credit: Douglas Levere, University at Buffalo.

The advancement suggests an important step toward helping fuel cell technology live up to its potential as a pollution-free provider of electricity for cars, trucks, trains, airplanes, and other heavy-duty vehicles.

Balancing Catalyst Durability and Efficiency

“For years, the scientific community has struggled to balance this tradeoff. We can make low-cost that are effective but degrade too easily. Or we’ve made them very stable, but their performance couldn’t match platinum. With this work, we’ve taken a step toward solving this problem,” says the study’s corresponding author, Gang Wu, PhD, professor in the Department of Chemical and Biological Engineering in the School of Engineering and Applied Sciences.

Innovative Approach in Catalyst Fabrication

The new study addressed this limitation during a fabricating process called pyrolysis, which involves using extremely hot temperatures to combine materials.

During pyrolysis, researchers bonded four nitrogen atoms to the iron in a high-temperature chamber. They then embedded this material into a few layers of graphene, which is a tough, light, and flexible form of carbon.

Usually, this process occurs within a chamber featuring an inert gas, such as argon. However, this time researchers fed hydrogen into the chamber to create a mixture of 90% argon and 10% percent hydrogen.

As a result, researchers were able to more precisely control the makeup of the catalyst. Specifically, they were able to place two different iron-nitrogen-carbon compounds (one contained 10 carbon atoms, the other contained 12 carbon atoms) in positions that support durability and efficiency.

The resulting catalyst reached initial fuel cell performance well beyond the Department of Energy’s goal for 2025. It also proved more durable than most iron-nitrogen-carbon catalysts, approaching a typical low-platinum cathode used for fuel cells.

Reference: “Tuning the thermal activation atmosphere breaks the activity–stability trade-off of Fe–N–C oxygen reduction fuel cell catalysts” by Yachao Zeng, Chenzhao Li, Boyang Li, Jiashun Liang, Michael J. Zachman, David A. Cullen, Raphael P. Hermann, E. Ercan Alp, Barbara Lavina, Stavros Karakalos, Marcos Lucero, Bingzhang Zhang, Maoyu Wang, Zhenxing Feng, Guofeng Wang, Jian Xie, Deborah J. Myers, Jean-Pol Dodelet and Gang Wu, 5 December 2023, Nature Catalysis.

DOI: 10.1038/s41929-023-01062-8

In addition to UB, the collaborative research team included members from the following organizations: Argonne National Laboratory; Indiana University–Purdue University Indianapolis; the National Institute of Scientific Research in Vareness, Quebec; Oak Ridge National Laboratory; Oregon State University; the University of Pittsburgh; and the University of South Carolina.

The study was supported by the U.S. Department of Energy.

Be the first to comment on "Toward a Green Future: Scientists Identify Key Ingredient for Affordable Fuel Cell Catalysts"