Researchers at Johannes Gutenberg University have decoded the history of the Roman mill complex of Barbegal in France using calcium carbonate deposits from the site. These findings reveal the mills’ operational life and the adaptations in water management needed over time, offering a rare insight into ancient industrial engineering.

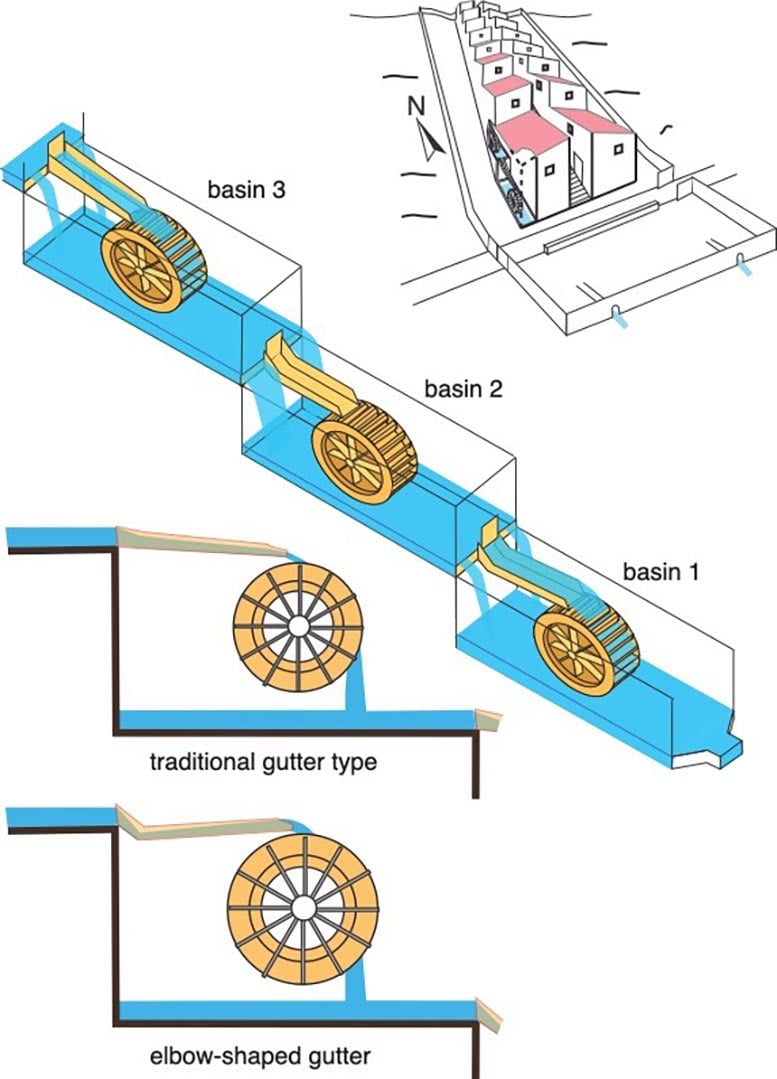

Archaeologists face a major challenge when studying buildings of which only ruins remain. This was a particular challenge for the remnants of the Roman water mills in Barbegal in Southern France, dating back to the 2nd century CE. This unique industrial complex consisted of 16 water wheels placed in parallel rows, eight on the east and eight on the west side, which were operated in a waterfall-like arrangement.

Previously, very little information could be derived from the site, except that the wheels were supplied by an aqueduct that brought water from the surrounding hills. The discovery of a coin issued during the reign of Emperor Trajan in a basin above the mill complex, along with the structural characteristics of the site, suggests that the mill was in use for about 100 years. However, the type of mill wheels, their function, and how they were employed have remained a mystery until now.

Carbonate fragment from the Barbegal mills, formed on wood of the mill machinery, with imprints of wood and traces of woodworking. Credit: Philippe Leveau

Historical Investigation Through Geoarchaeology

A new study led by Johannes Gutenberg University researchers has uncovered the history of the mill complex using calcium carbonate deposits now stored in the Archaeological Museum of Arles. In their study, recently published in Geoarchaeology, the researchers found that these deposits had formed towards the end of the roughly 100-year operational life of the Barbegal water mills on the sides and base of the wooden supply system that conveyed the water to the wheels.

“We show that it is possible to reconstruct to a large extent the history of a water mill on the basis of such carbonate deposits,” stated Professor Cees W. Passchier from Johannes Gutenberg University Mainz (JGU), head of the JGU team. First, the researchers had to fit some of the 140 stored pieces together like a jigsaw puzzle, then they analyzed the layers using various techniques, including mass spectrometry.

Sketch of the Barbegal mill complex with three water basins with mill wheels and water flumes. The lower basins probably had elbow-shaped flumes. Credit: Cees Passchier

Insights from Carbonate Deposits

“We were able to show, for example, that wooden water wheels and water channels had to be replaced after three to eight years. In at least one case, an old water wheel was replaced by a larger one,” said Passchier. The researchers drew this conclusion from the unusual shape of the carbonate deposits that had formed in the water channel. While the lower and earlier layers indicate that water levels must have originally been relatively low, upper and later carbonate layers indicate a higher water level.

The possibility that there was originally less water flowing through the water channel which was subsequently increased was rejected by the researchers. They established that – for a gently sloping water channel and low water level – the amount of water provided would not have been sufficient to drive a mill wheel. Therefore, the inclination of the water channel must have been altered, from what was at first a steeper angle with a low water level to a shallower slope transporting water at a correspondingly higher level.

Hollow carbonate fragment from the Barbegal mills, possibly from a spoke of the wooden millwheel. Credit: Philippe Leveau

“The entire structure of this water mill must have been modified,” said Passchier. “If you uplift the water channel alone, the water tends to splatter, losing the power to drive the wheel efficiently. Thus, when you uplift the water channel, you also need a larger water wheel.” In fact, a section of carbonate deposit formed on the water wheel corroborates this conclusion as it does not contain all the carbonate layers but only those of the latter years of operation.

Operational Dynamics and Seasonal Patterns

Using isotope analysis of the carbonate layers, the researchers were even able to ascertain the operating periods before which parts of the mill required renewal. Carbonate contains oxygen and the relative ratios of oxygen isotopes differ depending on water temperature. Based on the isotope composition in the carbonate layers, the researchers were able to infer water temperatures and thus identify the seasons in which the layers were deposited. They concluded that the carbonate from the samples in the Archaeological Museum in Arles had been deposited in the water channels over a period of seven to eight years.

“The uppermost and thus youngest carbonate layer contains mollusk shells and fragments of wood, showing that the mill must have been abandoned by then and was disintegrating. The water continued to flow for a while so that carbonate deposits also continued to form, but maintenance of the water channels ceased,” said Passchier.

Independent Operation of Water Mills

The researchers were able to answer yet another question. It was not previously known whether the mills had been run in combination by a single operator or whether the 16 water wheels had been used independently of each other. Judging from the layers of three investigated water channels, which are clearly different from each other, the mills were in operation separately – at least towards the end of their lifetime. Moreover, the western side of the complex was abandoned earlier than the eastern side. Finally, long pieces of carbonate from the water channels were later used as partition screens in a water basin for other industrial purposes after the mills had already been abandoned.

Reference: “Operation and decline of the Barbegal mill complex, the largest industrial complex of antiquity” by Cees W. Passchier, Gül Sürmelihindi, Pierre-Louis Viollet, Philippe Leveau and Christoph Spötl, 28 June 2024, Geoarchaeology.

DOI: 10.1002/gea.22016

Be the first to comment on "Ancient Ruins Reveal the Engineering Marvels of 1800-Year-Old Roman Mills"