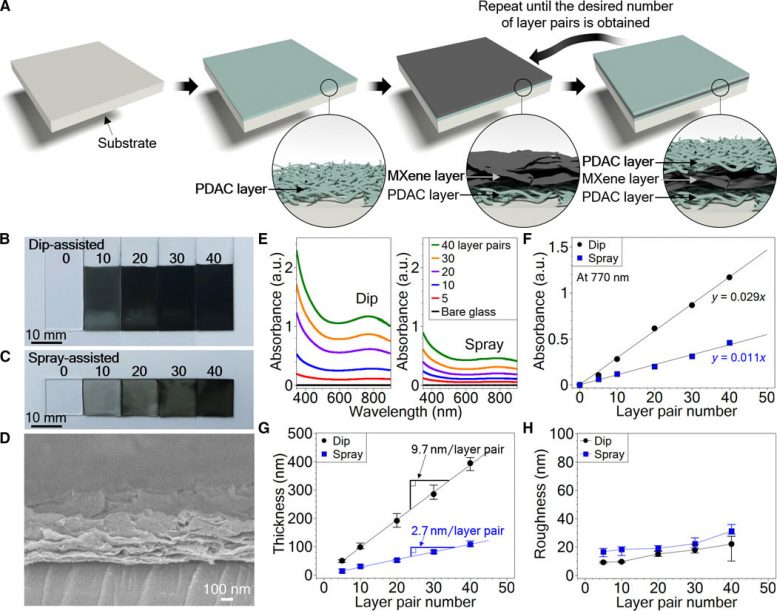

Fig. 1 Structural and morphological characterizations of MXene multilayers.(A) Schematic of the PDAC/MXene LbL assembly process. Images of (B) immersion and (C) spray assembly of multilayer coatings of varying number of layer pairs on glass. (D) A cross-sectional SEM image of the multilayer coating. (E) Ultraviolet–visible (UV-vis) spectra of MXene multilayers on glass. (F) Absorbance values at 770 nm versus number of layer pairs. a.u., arbitrary units. (G) Growth profile of the multilayers on glass. (H) Root-mean-square (RMS) roughness versus number of layer pairs. Hyosung An, et al., Science Advances 9 Mar 2018: Vol. 4, no. 3, eaaq0118; DOI: 10.1126/sciadv.aaq0118

A team of researchers from the College of Engineering at Texas A&M University have developed a mechanically robust conductive coating that can maintain performance under heavy stretching and bending.

Stretchable, bendable, and foldable electronics are crucial for the development of emerging technologies like adaptive displays, artificial skin, and biometric and wearable devices. This presents a unique challenge of balancing electronic performance and mechanical flexibility. The difficulty lies in finding a material that can withstand a wide array of deformations, like stretching, bending, and twisting, all while maintaining electrical conductivity. Adding to the challenge is the need for this conductivity to be engineered into a variety of different surfaces, such as cloth, fiber, glass, or plastic.

A collaborative team from the Artie McFerrin Department of Chemical Engineering and the Department of Materials Science and Engineering led by Dr. Jodie Lutkenhaus, associate professor and holder of the William and Ruth Neely Faculty Fellowship, has solved this problem through the development of a new surface-agnostic stretchable, bendable and foldable conductive coating, opening the door for a wide variety of flexible electronics.

Two-dimensional metal carbides (MXenes) were chosen as the main focus of the research as previous research has shown them to have a metallic-like conductivity. The previous research on MXenes has focused primarily on the materials in the form of sheets. Although these sheets have the desired conductivity, they are not stretchable and their integration into different surfaces has not been shown.

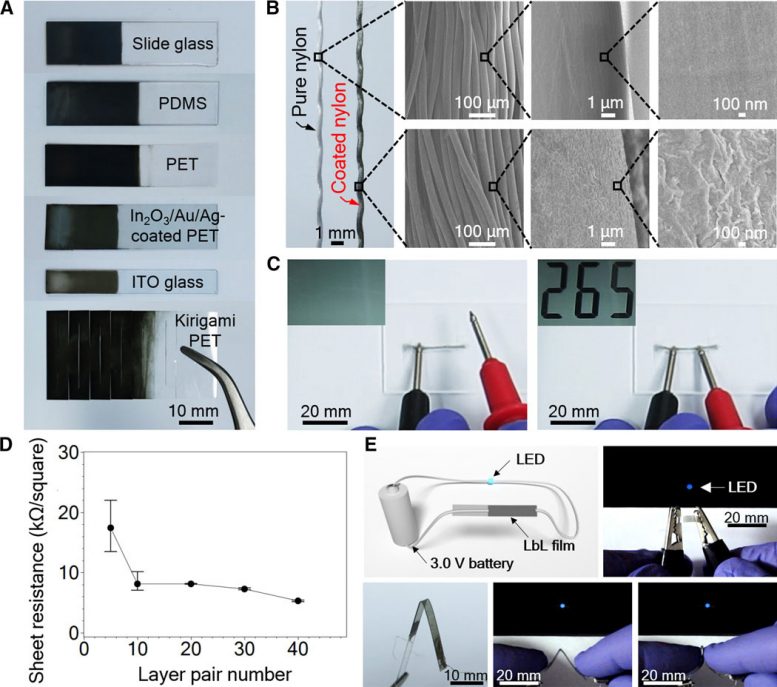

Fig. 2 Surface-agnostic conductive coatings.(A) Digital images of 40-layer-pair coatings on various substrates (sheet resistance of coatings on slide glass, PDMS, PET, and kirigami PET: 7, 7, 4, and 4 kilohm per square, respectively). (B) A digital image and SEM images of bare nylon fiber and 20-layer-pair–coated nylon fiber. (C) Images to demonstrate conductive coating on nylon fiber (R = 26.5 megohm). (D) Sheet resistance of the MXene multilayers on glass. (E) Schematic illustration of an electric circuit with a battery, a light-emitting diode (LED), and the MXene multilayer (LbL film). Digital images to demonstrate the conductive coating on PET under bending and folding. Hyosung An, et al., Science Advances 9 Mar 2018: Vol. 4, no. 3, eaaq0118; DOI: 10.1126/sciadv.aaq0118

Rather than using MXene sheets, the Texas A&M research team created MXene coatings through the sequential adsorption of negatively charged MXene sheets and positively charged polyelectrolytes using an aqueous assembly process known as layer-by-layer (LbL) assembly (See image 1-A). The results of this process, described in depth in the latest issue of Science Advances, demonstrate that MXene multilayer coatings that can undergo large-scale mechanical deformation while maintaining a high level of conductivity (see video). The team has also successfully deposited the MXene multilayer coatings onto flexible polymer sheet, stretchable silicones, nylon fiber, glass, and silicon.

Reference: “Surface-agnostic highly stretchable and bendable conductive MXene multilayers” by Hyosung An, Touseef Habib, Smit Shah, Huili Gao, Miladin Radovic, Micah J. Green and Jodie L. Lutkenhaus, 9 March 2018, Science Advances.

DOI: 10.1126/sciadv.aaq0118

Be the first to comment on "Chemical Engineers Develop a New Conductive Coating for Flexible Electronics"