Researchers have developed a novel solvent sieve method to create highly efficient and stable perovskite light-emitting diodes (PeLEDs) with unparalleled performance. Credit: SciTechDaily.com

Groundbreaking solvent sieve method enhances perovskite light-emitting diode performance, achieving unprecedented efficiency and operational lifetime.

Using a simple solvent sieve method, researchers from the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS) have taken the lead in developing highly efficient and stable perovskite light-emitting diodes (PeLEDs) with record performance.

The study was published today (February 5) in Nature Photonics.

Perovskites are one of the most promising optoelectronic materials due to their excellent optoelectronic performance and low preparation cost. Compared with traditional organic light-emitting diodes (OLEDs), PeLEDs have a narrower light-emitting spectrum and superior color purity, thus showing great application potential in display and lighting.

Tackling PeLED Stability Challenges

However, despite significant progress in efficiency, low operational stability has long limited the practical application of PeLEDs. In particular, a limited understanding of the cause of perovskite instability has greatly hindered the development and commercialization of PeLEDs.

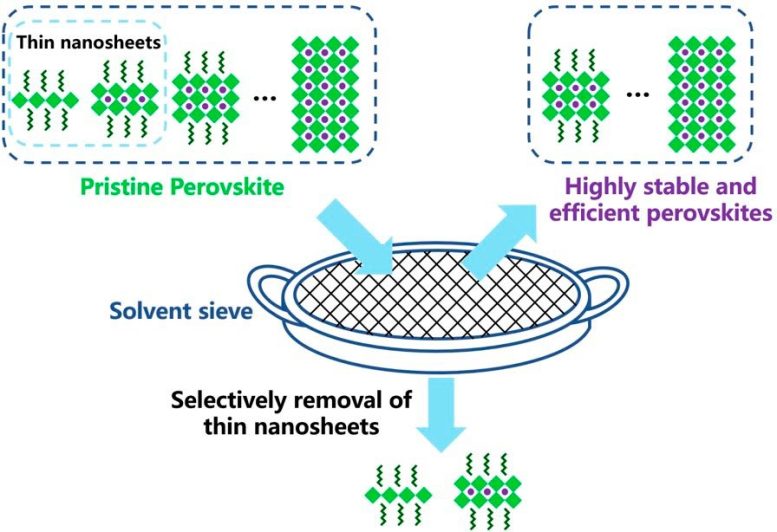

Based on an in-depth analysis of the fine nanostructures of perovskites, the researchers identified the perovskites’ defective low n-phase as the key source of perovskite instability. The low quality of the low n-phase, which contained only one or two layers of lead ions, originated from the rapid and uncontrollable crystallization process.

Inspired by the process of separating sand of different sizes with a sieve, the researchers proposed a solvent sieve method to screen out these undesirable low n-phases.

According to the researchers, the solvent sieve is a combination of polar and nonpolar solvents. The polar solvent acts as a mesh that interacts with perovskites, while the nonpolar solvent acts as a framework that does not affect perovskites. The researchers adjusted the ratio of polar solvents to effectively remove the defective low n-phases.

Record-Setting Performance and Stability

The PeLEDs based on the sieved perovskites achieved an operating lifetime of more than 5.7 years under normal conditions (luminance of 100 cd/m2), more than 30 times longer than the untreated device. This record lifetime is also the highest value reported to date for green PeLEDs, reaching the fundamental threshold for commercial application.

In addition, these PeLEDs achieved a record high external quantum efficiency (EQE) of 29.5%, significantly improving the efficiency of converting electricity to light.

When exposed to ambient air (50±10% humidity), the device can maintain 75% of its film photoluminescence quantum yield and 80% of its EQE for more than 100 days, thus showing excellent stability.

This solvent sieve method not only significantly improves the luminescence performance and stability of PeLEDs, but also paves the way for the future development and application of perovskites with unique nanostructures and excellent luminescence performance.

Reference: “Phase dimensions resolving of efficient and stable perovskite light-emitting diodes at high brightness” by Shuo Ding, Qiangqiang Wang, Wencui Gu, Zhaobing Tang, Bo Zhang, Chunyan Wu, Xuanyu Zhang, Hao Chen, Xinyu Zhang, Rui Cao, Tao Chen, Lei Qian and Chaoyu Xiang, 5 February 2024, Nature Photonics.

DOI: 10.1038/s41566-023-01372-0

Be the first to comment on "Revolutionizing Optoelectronics With Solvent Sieve Perovskite LEDs"