Researchers from the University of Connecticut and colleagues have created a highly durable, lightweight material by structuring DNA and then coating it in glass. The resulting product, characterized by its nanolattice structure, exhibits a unique combination of strength and low density, making it potentially useful in applications like vehicle manufacturing and body armor. (Artist’s concept.)

Researchers have developed a highly robust material with an extremely low density by constructing a structure using DNA and subsequently coating it in glass.

Materials possessing both strength and lightness have the potential to enhance everything from automobiles to body armor. But usually, the two qualities are mutually exclusive. However, researchers at the University of Connecticut, along with their collaborators, have now crafted an incredibly strong yet lightweight material. Surprisingly, they achieved this using two unexpected building blocks: DNA and glass.

“For the given density, our material is the strongest known,” says Seok-Woo Lee, a materials scientist at UConn. Lee and colleagues from UConn, Columbia University, and Brookhaven National Lab report the details on July 19 in Cell Reports Physical Science.

Strength is relative. Iron, for example, can take 7 tons of pressure per square centimeter. But it’s also very dense and heavy, weighing 7.8 grams/cubic centimeter. Other metals, such as titanium, are stronger and lighter than iron. And certain alloys combining multiple elements are even stronger. Strong, lightweight materials have allowed for lightweight body armor, better medical devices, and made safer, faster cars and airplanes.

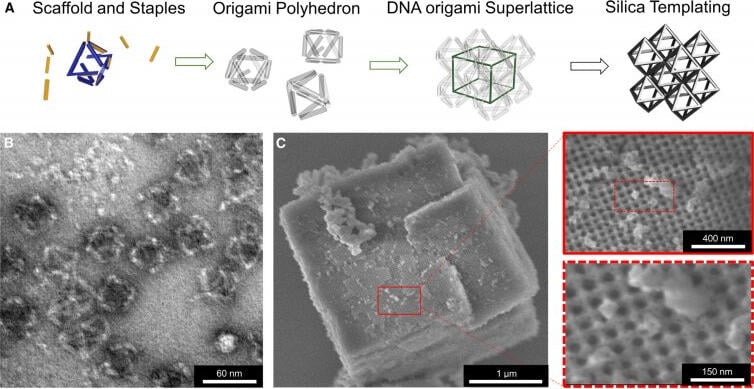

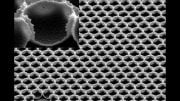

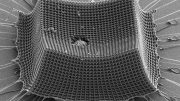

Materials scientists from UConn and Brookhaven National Laboratory built an exceptionally strong, lightweight material out of DNA and glass. The series of images at the top (A) show how the skeleton of the structure is assembled with DNA, then coated with glass. (B) shows a transmission electron microscope image of the material, and (C) shows a scanning electron microscope image of it, with the two right-hand panels zooming in to features at different scales. Credit: University of Connecticut

The easiest way to extend the range of an electric vehicle, for example, is not to enlarge the battery but rather make the vehicle itself lighter without sacrificing safety and lifetime. But traditional metallurgical techniques have reached a limit in recent years, and materials scientists have had to get even more creative to develop new lightweight high strength materials.

Now, Lee and colleagues report that by building a structure out of DNA and then coating it with glass, they have created a very strong material with very low density. Glass might seem a surprising choice, as it shatters easily. However, glass usually shatters because of a flaw – such as a crack, scratch, or missing atoms – in its structure. A flawless cubic centimeter of glass can withstand 10 tons of pressure, more than three times the pressure that imploded the Oceangate Titan submersible near the Titanic last month.

It’s very difficult to create a large piece of glass without flaws. But the researchers knew how to make very small flawless pieces. As long as the glass is less than a micrometer thick, it’s almost always flawless. And since the density of glass is much lower than metals and ceramics, any structures made of flawless nano-sized glass should be strong and lightweight.

The team created a structure of self-assembling DNA. Almost like Magnatiles, pieces of DNA of specific lengths and chemistry snapped themselves together into a skeleton of the material. Imagine the frame of a house or building, but made of DNA.

Oleg Gang and Aaron Mickelson, nanomaterials scientists at Columbia University and Brookhaven’s Center for Functional Nanomaterials, then coated the DNA with a very thin layer of glass-like material only a few hundred atoms thick. The glass only just coated the strands of DNA, leaving a large part of the material volume as empty space, much like the rooms within a house or building.

The DNA skeleton reinforced the thin, flawless coating of glass making the material very strong, and the voids comprising most of the material’s volume made it lightweight. As a result, glass nanolattice structures are four times higher in strength but five times lower in density than steel. This unusual combination of lightweight and high strength has never been achieved before.

“The ability to create designed 3D framework nanomaterials using DNA and mineralize them opens enormous opportunities for engineering mechanical properties. But much research work is still needed before we can employ it as a technology,” says Gang.

The team is currently working with the same DNA structure but substituting even stronger carbide ceramics for glass. They have plans to experiment with different DNA structures to see which makes the material strongest. Future materials based on this same concept have great promise as energy-saving materials for vehicles and other devices that prioritize strength. Lee believes that DNA origami nanoarchitecture will open a new pathway to create lighter and stronger materials that we have never imagined before.

“I am a big fan of Iron Man movies, and I have always wondered how to create a better armor for Iron Man. It must be very light for him to fly faster. It must be very strong to protect him from enemies’ attacks. Our new material is five times lighter but four times stronger than steel. So, our glass nanolattices would be much better than any other structural materials to create an improved armor for Iron Man.”

Reference: “High-strength, lightweight nano-architected silica” by Aaron Michelson, Tyler J. Flanagan, Seok-Woo Lee and Oleg Gang, 27 June 2023, Cell Reports Physical Science.

DOI: 10.1016/j.xcrp.2023.101475

This will probably sound like a stupid question , so i hope i word this right .

When its said here DNA do they mean like the structure that makes the glass ,( i know i maybe moduls confused). so the silica(glass) has a lattace structure naturally , and the dna structure reinforces it similar to wire running through glasson the doors in hospitals. or are they refering to living dna or just the acids they put together ? Where does the dna come from ? and if it is metal used i.e iron or titatium ( though i think they were showing examples of strength to weight as a comparasion to their product)would the shape of the struceture be different acording to there own structure?

Please excuse any poor spelling and convoluted wording , and thank you for any clarifications given 🙂

There’s no stupid questions, only stupid answers, and that’s where I come in. I know virtually zero about nanomaterials, so take this with a giga-nanogram of salt. As popular as nanomaterial science was in the 2000s, daily-life applications were far off, so I didn’t learn enough.

It isn’t clear from the article, and there’s no more detail in the study. It sounds like they used short strands of (dead) DNA as a lattice on which to grow glass crystals. I think the magic is in the self-assembling lattice, and this nano-shape seems to add strength (think diamonds or buckyballs or graphene). Alternately or in tandem, they’re also describing the DNA as reinforcing the glass, so in that case it would be acting like a fiberglass, only using short helicoid protein strands and glass, instead of glass strands and plastic. Higher strength, need less glass, so less weight. I really like this kind of research. Stronger safer more-efficient cars is just one application for a new super-strong lightweight glass material. I want a transparent airplane, or at least a thin microwavable coffee mug that won’t shatter.

But I’m here to quibble and make jokes. “The easiest way to extend the range of an electric vehicle is not to enlarge the battery but rather make the vehicle itself lighter”, no, buying a bigger battery is just so much easier than shedding weight; ask anyone on an F1 race team, or a nanotech research team, or a diet. Still, above low speed your biggest concern is air resistance — on the highway, anyway. In the city, lightness matters with stop-go traffic, but that just makes the easiest way driving through red lights.

I’m no Scientist (or “Alien Believer” by any means but I’d like to bet they’re trying to back engineer ideas from recovered Craft which has often been referred to as having the appearance of Extremely THIN Aluminium foil which is very malleable and when scrunched into Any shape it retracts back to it’s originsl shape.

I see stories about new miracle metals and alloys regularly but these never seem to get to market. Why not?

Because the deep state grabs them up and uses them against the people.

Possibly because it could not be scaled up for production economically, or it is very difficult to shape. Materials science is very important, but engineering and design is what brings stuff to market. Good materials that is hard to engineer won’t attract investments, at least for the larger market.

Just don’t use it to reinforce a submarine hull🤨

The legend is true….Mithril

When I was in school we were taught that glass was a slow moving liquid

You were taught incorrectly. Glass *can* flow, but it only does so in a measurable way over geologic time. The fact that very old window panes are thicker at the bottom than at the top was misinterpreted as demonstrating glass as a very viscous liquid, but the truth is much more mundane. Before “float glass” was invented in the middle of the 20th Century, glass panes had a thick side and a thin side. It was simply customary to install them with the thick side down.

Glass indeed deforms (slowly) when placed under stress, but it’s *elastic* and returns to its original shape (slowly) when the stress is removed.

If you can create a lattice with DNA and coat it with glass. How difficult would it be to then coat the glass with a H2 absorbing compound. Or an electrically conducting compound to create the electrode of a battery.

They did similar in 1986, Star Trek IV, The Voyage Home… They called it Transparent Aluminum. Ok, it was thicker material, and it was a movie, but it looked like glass, and could hold enough water to support a humpback whale…

I was going to mention that Star Trek movie. You beat me to it. Kudos to you.

Aluminum Oxynitride is real. It’s commonly known as AlON, and it’s both very strong and very transparent. One problem is that it’s a ceramic, not a metal, which makes it impossible to shape once it’s been “cast”. It’s also not practical to try to make very large pieces of it.

A small replaceable ALON outer surface lens protector would be perfect for spacecraft. The hull would only need a tiny holes for vr-ir camera viewing of critical areas of the ship. The camera video information is relayed to flight crew on several displays within the spacecraft. This removes the need for large viewports.

A science website should get the language correct. You can’t be 5 times lighter. That would be -4 (1 – 5 = -4.) What you mean is 1/5 as heavy.

Nah… While specifically you are correct; Most people with a reasonable intellect got the context. Good for you, but not everyone in the world are democrats.

Agreed. Multiples imply larger, fractions imply smaller. The modern dumbed down culture seems to accept less accurate, but more expedient forms as discussed here. To me it suggests a lack of regard for accuracy in communication and respect for education.

A science website should actually use ‘as massive’ (mass) – not, “as heavy.”

Also, you’ve made your steel weigh “1”, just to fit your Maths resulting in 5x lighter equalling -4 (yet you can’t see the new material weighing 0.2 – “5x lighter”).

The new material is 5x less massive – deal with it.

Seeing it’s not pure glass. Is it still transparent. Or at least opaque?

Lets make a submersible with that material an dive down to Titanic

Glass blowing class 201

I wonder if they tried silicone or plastic to see if they get the same lattic.

Steel isn’t light, so how can something be 5x lighter ?

It is 1/5th the weight.

On another article, miniaturized atomic clock, they didn’t make a clock, then shrink it. It is a miniature clock.

Why isn’t steel light? Compared to what? Also, why does the weight of the steel have to be “1” and then result in 5x lighter being -4? Why can’t you calculate the “DNA glass” to be 0.2, as that’s obviously, you’d think, 5x lighter than 1. Or even, imagine the weight of the steel to be 5, making the DNA glass 1?

Is it really that hard to understand?

Are these the same people that refer to immigrants as illegal aliens. Yet have a problem with referring to 1/5 the weight as 5x lighter. Just wondering. I mean let’s not be you know. You know. I need not say it.

It’s transparent Aluminum, Captain!