Researchers have developed a positive electrode material for aluminum-ion batteries using an organic redox polymer, which has shown a higher capacity than graphite. The electrode material successfully underwent 5,000 charge cycles, retaining 88% of its capacity at 10 C, marking a significant advancement in aluminum battery development.

A research group has created an organic redox polymer for use as a positive electrode in aluminum-ion batteries.

Aluminum-ion batteries are emerging as a potential successor to traditional batteries that rely on hard-to-source and challenging-to-recycle materials like lithium. This shift is attributed to aluminum’s abundance in the Earth’s crust, its recyclability, and its comparative safety and cost-effectiveness over lithium.

Nonetheless, the advancement of aluminum-ion batteries remains in the early stages, as researchers are still searching for appropriate electrode materials that can deliver adequate storage capacity. A breakthrough in this field has recently been made by a research team, led by Prof. Dr. Birgit Esser of the University of Ulm and Prof. Dr. Ingo Krossing and Prof. Dr. Anna Fischer of the University of Freiburg, and headed by Gauthier Studer. The team has developed a positive electrode material composed of an organic redox polymer based on phenothiazine.

In the experiment, aluminum batteries with this electrode material stored a previously unattained capacity of 167 milliampere hours per gram (mAh/g). The organic redox polymer thus surpasses the capacity of graphite, which has mostly been used as an electrode material in batteries to date. The results appeared in the journal Energy & Environmental Science.

Electrode material inserts complex aluminum anions

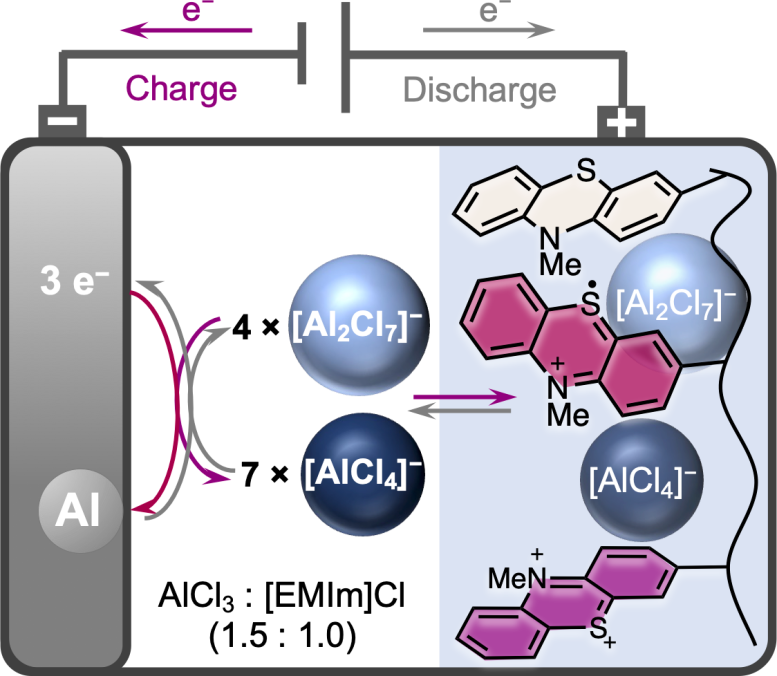

The electrode material is oxidized during the charging of the battery, thereby taking up complex aluminate anions. In this way, the organic redox polymer poly(3-vinyl-N-methylphenothiazine) manages to insert two [AlCl4]− anions reversibly during charging. The researchers used the ionic liquid ethylmethylimidazolium chloride as an electrolyte with added aluminum chloride.

The schematic diagram of the battery shows the redox process in which the electrode material is oxidized and aluminate anions are deposited. Credit: Birgit Esser / University of Freiburg

“The study of aluminum batteries is an exciting field of research with great potential for future energy storage systems,” says Gauthier Studer. “Our focus lies on developing new organic redox-active materials that exhibit high performance and reversible properties. By studying the redox properties of poly(3-vinyl-N-methylphenothiazine) in chloroaluminate-based ionic liquid, we have made a significant breakthrough by demonstrating for the first time a reversible two-electron redox process for a phenothiazine-based electrode material.”

After 5,000 charge cycles at 10 C, the battery retains 88 percent of its capacity

Poly(3-vinyl-N-methylphenothiazine) deposits the [AlCl4]− anions at potentials of 0.81 and 1.65 volts and provides specific capacities of up to 167 mAh/g. In contrast, the discharge capacity of graphite as electrode material in aluminum batteries is 120 mAh/g. After 5,000 charge cycles, the battery presented by the research team still has 88 percent of its capacity at 10 C, i.e. at a charge and discharge rate of 6 minutes. At a lower C rate, i.e. a longer charge and discharge time, the battery returns unchanged to its original capacities.

“With its high discharge voltage and specific capacity, as well as its excellent capacity retention at fast C rates, the electrode material represents a major advance in the development of rechargeable aluminum batteries and thus of advanced and affordable energy storage solutions,” says Birgit Esser.

Reference: “On a high-capacity aluminium battery with a two-electron phenothiazine redox polymer as a positive electrode” by Gauthier Studer, Alexei Schmidt, Jan Büttner, Maximilian Schmidt, Anna Fischer, Ingo Krossing and Birgit Esser, 22 May 2023, Energy & Environmental Science.

DOI: 10.1039/D3EE00235G

The project was funded by the German Research Foundation (DFG) (project AMPERE within SPP 2248 – Polymer-based Batteries, POLiS – EXC 2154, livMatS – EXC 2193) as well as by the Deutsche Bundesstiftung Umwelt, the bwForCluster JUSTUS 2, the Eva Mayr-Stihl-Stiftung (Saltus!) and the Land Baden-Württemberg (bwHCP).

Be the first to comment on "Scientists Develop Aluminum-Ion Batteries With Improved Storage Capacity"