The gold nugget obtained from computer motherboards in three parts. The largest of these parts is around five millimeters wide. Credit: ETH Zurich / Alan Kovacevic

Transforming base materials into gold was one of the elusive goals of the alchemists of yore. Now Professor Raffaele Mezzenga from the Department of Health Sciences and Technology at ETH Zurich has accomplished a modern parallel to this quest. While he hasn’t changed one chemical element into gold as alchemists dreamed, he has successfully extracted gold from electronic waste using a byproduct of the cheesemaking process.

Electronic waste contains a variety of valuable metals, including copper, cobalt, and even significant amounts of gold. Recovering this gold from disused smartphones and computers is an attractive proposition in view of the rising demand for the precious metal. However, the recovery methods devised to date are energy-intensive and often require the use of highly toxic chemicals. Now, a group led by ETH Professor Mezzenga has come up with a very efficient, cost-effective, and above all far more sustainable method: with a sponge made from a protein matrix, the researchers have successfully extracted gold from electronic waste.

Selective gold adsorption

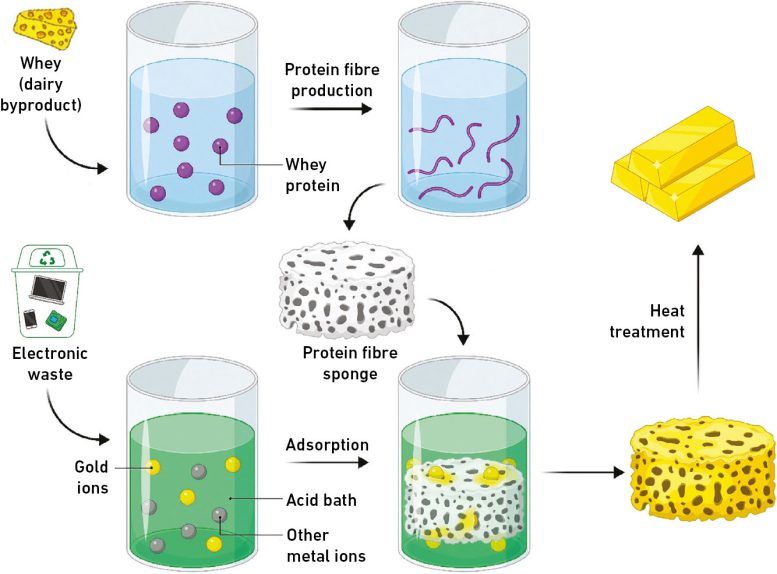

To manufacture the sponge, Mohammad Peydayesh, a senior scientist in Mezzenga’s Group, and his colleagues denatured whey proteins under acidic conditions and high temperatures, so that they aggregated into protein nanofibrils in a gel. The scientists then dried the gel, creating a sponge out of these protein fibrils.

To recover gold in the laboratory experiment, the team salvaged the electronic motherboards from 20 old computer motherboards and extracted the metal parts. They dissolved these parts in an acid bath so as to ionize the metals.

How the gold is recovered: Gold ions adhere to a sponge of protein fibrils. Credit: Peydayesh M et al. Advanced Materials, 2024, adapted

When they placed the protein fiber sponge in the metal ion solution, the gold ions adhered to the protein fibers. Other metal ions can also adhere to the fibers, but gold ions do so much more efficiently. The researchers demonstrated this in their paper, which they have published in the journal Advanced Materials.

As the next step, the researchers heated the sponge. This reduced the gold ions into flakes, which the scientists subsequently melted down into a gold nugget. In this way, they obtained a nugget of around 450 milligrams out of the 20 computer motherboards. The nugget was 91 percent gold (the remainder being copper), which corresponds to 22 carats.

Economically viable

The new technology is commercially viable, as Mezzenga’s calculations show: procurement costs for the source materials added to the energy costs for the entire process are 50 times lower than the value of the gold that can be recovered.

Next, the researchers want to develop the technology to ready it for the market. Although electronic waste is the most promising starting product from which they want to extract gold, there are other possible sources. These include industrial waste from microchip manufacturing or from gold-plating processes. In addition, the scientists plan to investigate whether they can manufacture the protein fibril sponges out of other protein-rich byproducts or waste products from the food industry.

“The fact I love the most is that we’re using a food industry byproduct to obtain gold from electronic waste,” Mezzenga says. In a very real sense, he observes, the method transforms two waste products into gold. “You can’t get much more sustainable than that!”

Reference: “Gold Recovery from E-Waste by Food-Waste Amyloid Aerogels” by Mohammad Peydayesh, Enrico Boschi, Felix Donat and Raffaele Mezzenga, 23 January 2024, Advanced Materials.

DOI: 10.1002/adma.202310642

“…, the recovery methods devised to date are energy-intensive and often require the use of highly toxic chemicals.”

How does the new method differ from the former method(s) when acid baths and heating are still essential to the process, PLUS the acid treatment and high temperature ‘cooking’ of the whey! It may turn out that the new process is cheaper, but the claims about toxicity and energy consumption come across as rationalizations.

Why does the resultant gold product contain approximately 10% copper when they claim that their process has zero percent removal efficiency for copper? Something doesn’t add up here. I see that both the new and former processes depend on Aqua Regia to dissolve the gold from the electronics waste. That is probably the most dangerous chemical in the process; yet, they imply that their method doesn’t use toxic chemicals. Again, there is a disconnect between the claims and what I know about the chemistry of gold.