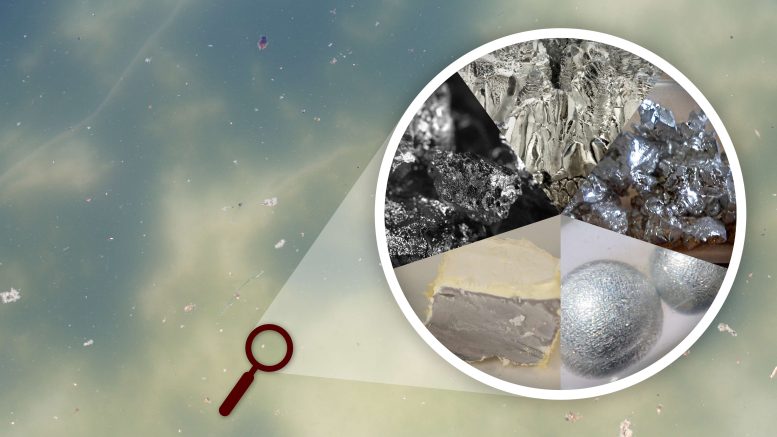

The water recovered from hydrocarbon reservoirs contains critical minerals that are key to many technical and industrial operations. Credit: Texas A&M Engineering

In an ironic twist, a treasure trove of critical minerals is dumped out with water considered too polluted and expensive to clean.

Texas A&M University researcher Dr. Hamidreza Samouei is investigating the components of produced water and says this waste byproduct of oil and gas operations contains nearly every element in the periodic table, including those of significant interest to national economies.

His goal is to treat the water using unwanted carbon dioxide (CO2) in stages to recover these valuable elements and ultimately produce fresh water for agricultural use once the processes are complete.

“Recognizing the latent value within produced water can offer tangible solutions to some of the world’s most pressing environmental challenges, from CO2 emissions to the increasing scarcity of certain minerals and water itself,” said Samouei, a research assistant professor in the Harold Vance Department of Petroleum Engineering.

Samouei’s “brine mining” research was featured in a January 2024 article in the Society of Petroleum Engineers’ Journal of Petroleum Technology titled “Liquid Goldmine: unlocking the Critical Mineral Potential of Produced Water using Carbon Dioxide.” He introduced the topic at the Middle East Water Week Conference and Exhibition held in December 2023 in Saudi Arabia and reported his most recent discoveries at the Annual Produced Water Society Conference on February 2024 in Houston, Texas.

Why is produced water thrown away?

Water accumulates in subsurface areas where geological functions happen, like hydrocarbon reservoirs, and it dissolves and stores vast quantities of minerals and other elements. During oil and gas operations, an average of six 42-gallon barrels of this “produced” water are recovered for every one barrel of oil, and in rare cases, up to a staggering ratio of 500 to 1. It is up to 10 times saltier than seawater and contains about 6,000 times more minerals.

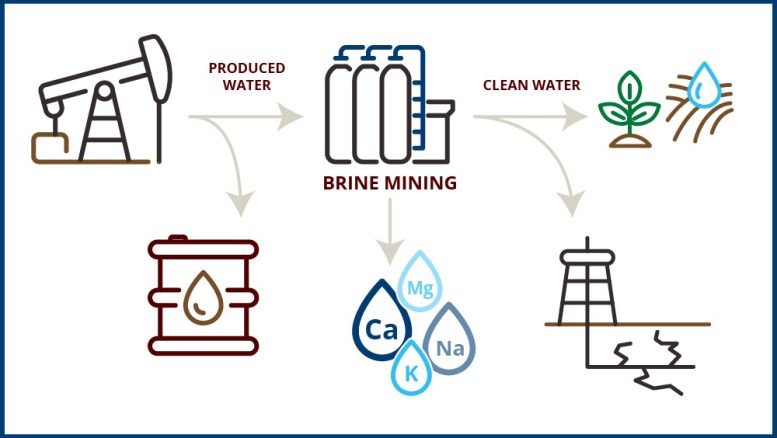

Once produced water is separated from oil, the intended process involves a brine mining process to recover critical minerals and other elements before the water is cleaned for specific agriculture operations or for use in fracturing operations to recover more oil. Credit: Texas A&M Engineering

In 2020, the annual global quantity of produced water recovered from oil and gas operations surpassed 240 billion barrels, with Texas alone recovering 33 million barrels daily. The oilfields of the Permian Basin in Texas generate more produced water than all other U.S. shale plays combined. Treating this vast volume is cost-prohibitive, so produced water is mainly considered a waste product and injected in subsurface disposal fields for safe containment.

The hidden values in brine

Since everything in produced water has never been cataloged, Samouei’s research began with the basics. He collected produced water samples around the U.S. and created a standardized method of analyzing the water’s content. That’s when he learned it contained nearly everything listed in the periodic table of elements.

Samouei’s findings included critical minerals like lithium, rubidium, cesium, gallium, and platinum group metals – substances fundamental to the current and future technologies advancing computer, energy, and transportation industries. More importantly, like other brines, produced water featured less expensive but abundant quantities of sodium, potassium, magnesium, and calcium – used in manufacturing processes, fertilizer production, and other industries.

All these minerals can be far more lucrative than the oil that comes up with produced water, so water reclamation costs could be easily offset by selling the recovered minerals.

A better treatment

Samouei explained that while desalinating produced water has been considered, the approach of first mining all the salt and minerals before treating the water had not been explored.

Much of his current research centers on developing the best flow of methods for extracting valuable minerals from brine in stages of refinement using CO2 desalination, which he says is “a groundbreaking approach to targeted mineral recovery from produced water.” The process includes a variety of filtration techniques, such as ultrafiltration and nanofiltration, and even utilizes reverse osmosis.

Commercialization potential

The research is creating a baseline for brine mining, whether using produced water or other brackish sources, but Samouei said further development would need a funding source. Government sponsors are concentrating on critical mineral mining in places such as the sea floor or even asteroids, not on something as close to home as produced water.

Samouei said he hopes to change the oil and gas industry’s view of produced water, first to see it as a lucrative means of receiving money and later, perhaps in 10 years, as a source for their own mining operations.

“Produced water may not be beautiful if we look at it as a waste,” he said, “but it will be impactful to the world’s next generations if we look at it as a resource.”

Reference: “Liquid Goldmine: Unlocking the Critical Mineral Potential of Produced Water Using Carbon Dioxide” by Jennifer Presley, 1 January 2024, Journal of Petroleum Technology.

The solution to pollution is NOT dilution, but rather finding a market for the ‘contaminants.’ There used to be a joke about how the Chicago slaughter houses used everything from pigs except the squeal. That should be an economic model for all industrial processes. The only ‘waste’ from industry is when they don’t find a market for the byproducts from their main production. However, extracting and purifying the dissolved components doesn’t come without expenses. The challenge is to find ways of economically producing the saleable byproducts.

Cost, cost, cost, is everything you have to know about mining. If a mining machine produces a ton of ore for $1.00 more than another…it disappears from use. If I sell you Rubidium for 5% more than you do. You’ll get ALL the business.

Price makes the difference between a resource (potential) and reserves (mineable).