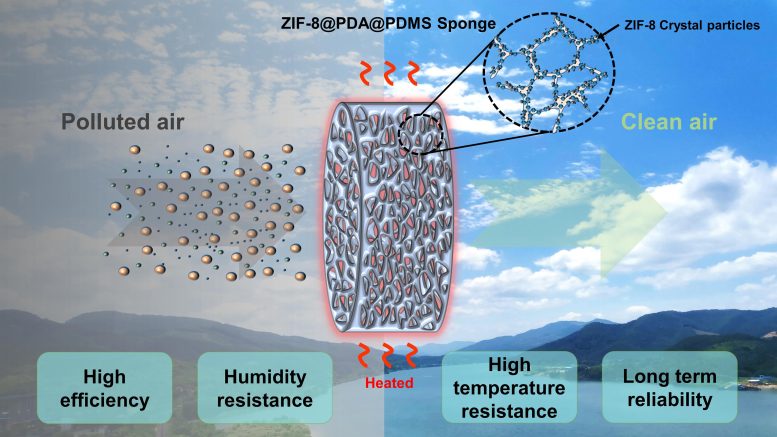

The ZIF-8@PDA@PDMS composite sponge with customizable shape achieves high-efficiency filtration of PM pollutants under high temperature and high humidity conditions. Credit: Yukui Gou, Fuzhou University

New air filter design promises strong potential for applications in automobiles and industry.

A high-performance composite sponge that works effectively to filter particulate matter in high temperature and high humidity environments has been designed by a team of researchers. Featuring excellent mechanical properties, the sponge is made of environmentally friendly materials. This filter has great potential for helping to fight air pollution in automobiles and in industry.

The work, by a team of Chinese researchers from Fuzhou University, is published today (October 3, 2022) in the journal Particuology.

Particulate matter from automobile exhaust and industrial chimneys poses a substantial danger to both humans and the environment. Problems related to gas pollution exists in countries around the world. Particulate pollution is especially dangerous for humans because it can impair the central nervous system and the respiratory system. Researchers have been working to build better air filters to solve the problem of air pollution and improve the quality of the environment. To this point, however, the air filters being developed have not performed well in harsh environments, where high temperatures, high humidity, or the need for long periods of filtration bring added challenges.

To build a better air filter, the team of scientists designed a three-dimensional particle capture device. They used a simple sacrificial template method to create a polydimethylsiloxane (PDMS) sponge. Next, they applied a polydopamine (PDA) coating onto the sponge skeleton using an in-situ loading method. Then, a large number of ZIF-8 particles were grown on the PDA coating. ZIF-8 is a metal-organic framework, a class of porous materials that are versatile in their structural and chemical tunability. Metal-organic frameworks exhibit good potential for applications in the fields of gas adsorption and air filtration. The abundant pores in the composite sponge provide good airflow and the ZIF-8 particles enhance the sponge’s filtration performance.

Particulate matter that comes from automobile exhaust and industrial chimneys requires filters to have high-temperature and high-humidity resistance, and good mechanical properties. Credit: Tartila

The team tested their sponge under high temperature (250 degrees Celsius / 482 degrees Fahrenheit) and high humidity (90 percent relative humidity) conditions that simulated an industrial high-temperature environment. The results at the high temperatures and humidity demonstrate the composite sponge’s strong potential for applications in industry.

Further testing of the composite sponge duplicated the conditions required for use in filtering automobile exhaust. Because the sponge can be easily shaped and has structural stability, it can be easily used in different scenarios, as needed. So the researchers prepared the composite sponge to fit at the exhaust pipe mouth. In the automobile exhaust tests, which simulated the exhaust emitted by automobiles during normal operation, the composite sponge achieved over 99 percent efficiency in removing particulate matter. Even after 65 hours of filtration, the composite sponge still achieved excellent performance.

“This study provides a new idea for designing 3D high-efficiency air filters that can adapt to harsh environments,” said Yuekun Lai, a professor at Fuzhou University. Because the composite sponge has good structural stability and can also be easily shaped, it is suitable for use in applications ranging from automobile exhaust to industrial chimneys to kitchen fans.

“In the next step, our research team will explore gas filters that can adapt to higher temperatures, as well as ways to treat certain components of air pollutants, not just particulate matter filtration,” said Lai. In this way, the researchers might expand the application scenarios of gas filters and also improve the potential for practical applications. “Our ultimate goal is to achieve a gas filter that can be used in a variety of environments, and a high-efficiency filter material with a variety of functions,” said Lai.

Reference: “Rational designed ZIF-8@PDA@PDMS composite sponge for efficient and sustainable particulate matter filtering under harsh environment” 3 October 2022, Particuology.

DOI: 10.1016/j.partic.2022.09.001

The research team includes Yukui Gou, Yuanye Hao, Weilong Cai, Jianying Huang, and Yuekun Lai from the College of Chemical Engineering, Fuzhou University. Cai, Huang, and Lai also work at the Qingyuan Innovation Laboratory.

The research is funded by the National Natural Science Foundation of China, Natural Science Funds for Distinguished Young Scholar of Fujian Province, and Natural Science Foundation of Fujian Province.

Be the first to comment on "New Air Filter Features Excellent Performance and Endurance in Harsh Environments"