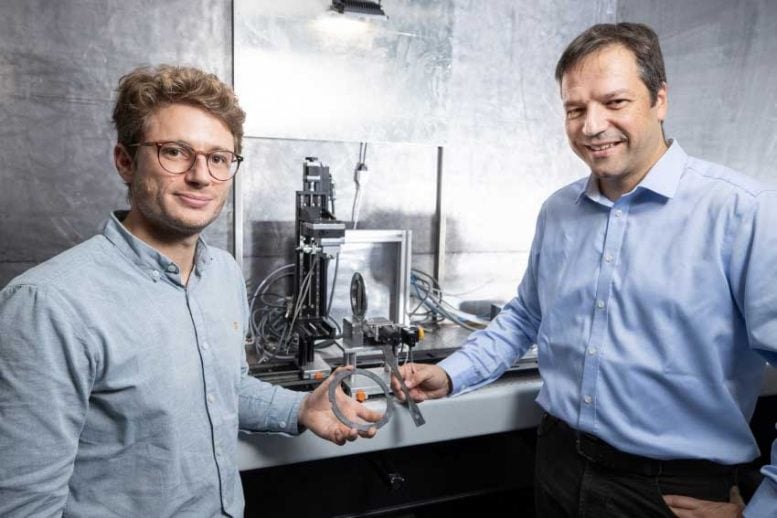

Matias Kagias (left) and Marco Stampanoni in front of the apparatus with which they examined the composites using the newly developed X-ray method. Both hold one of the workpieces that have been X-rayed. Credit: Paul Scherrer Institute/Mahir Dzambegovic

Researchers at the Paul Scherrer Institute PSI have improved a method for small-angle X-ray scattering (SAXS) to such an extent that it can now be used in the development or quality control of novel fiber-reinforced composites. This means that in the future, such materials can be investigated not only with X-rays from especially powerful sources such as the Swiss Light Source SLS, but also with those from conventional X-ray tubes. The researchers published their results today (November 12, 2019) in the journal Nature Communications.

Novel fiber-reinforced composites are becoming increasingly important as stable and lightweight materials. One example of this type of composite is carbon fiber reinforced polymers (CFRP), which are used in aircraft construction or in the construction of Formula 1 racing cars and sports bicycles. The properties of these materials depend to a large extent on how the tiny fibers are aligned and how they are arranged and embedded in the surrounding material, influencing the mechanical, optical, or electromagnetic behavior of the composites.

Matias Kagias fixes a sample in a clamp to position it in the X-ray path. Credit: Paul Scherrer Institute/Mahir Dzambegovic

To investigate the fiber’s orientation in such composites, researchers must look inside them. One could use small angle X-ray scattering (SAXS), exploiting the fact that X-rays are scattered when they penetrate matter. The resulting scattering pattern can then be used to obtain information about the interior of a sample and potentially the orientation of the fibers. However, the common SAXS methods have the disadvantage of being quite slow: It can take up to several hours to scan centimeter-sized specimens with the required resolution.

Observing the knotting of a carbon fiber ribbon

Researchers at the Paul Scherrer Institute PSI and ETH Zurich, together with colleagues from EPF Lausanne and the Danish spin-off company Xnovo Technology, have now succeeded in further developing the technology for practical applications. “The decisive factor was that we installed an array of X-ray lenses behind the sample. This makes it possible to detect multiple local scattering patterns that reflect the spatial inner structure of a sample with only one X-ray shot, enabling us to take a large number of consecutive images,” says Matias Kagias, the inventor of the method and a postdoctoral researcher in the PSI X-ray tomography group headed by Marco Stampanoni. As a proof of principle, the researchers used the new method to display fibers’ orientation in a carbon fiber ribbon during the knotting process. They acquired time-resolved X-ray projections at a rate of 25 images per second over a period of 11 seconds.

Applications in medicine and security are conceivable

The new method works not only with X-rays from synchrotron facilities such as the Swiss Light Source SLS, but also with beams from conventional X-ray tubes. Therefore, says Prof. Marco Stampanoni, “it is expected that this novel approach will find practical applications in medical devices and non-destructive testing as well as the area of homeland security.”

Reference: “Diffractive small angle X-ray scattering imaging for anisotropic structures” by Matias Kagias, Zhentian Wang, Mie Elholm Birkbak, Erik Lauridsen, Matteo Abis, Goran Lovric, Konstantins Jefimovs and Marco Stampanoni, 12 November 2019, Nature Communications.

DOI: 10.1038/s41467-019-12635-2

Be the first to comment on "New Breakthrough Offers Fast and Precise Look Into Fiber-Reinforced Composites"