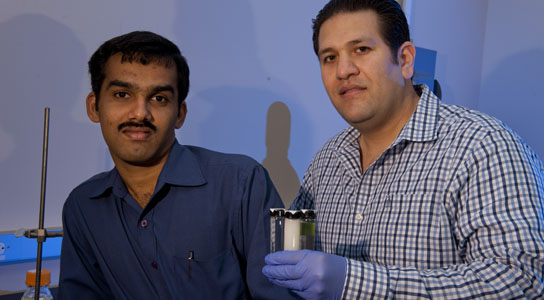

Rice University postdoctoral researcher Tharangattu Narayanan, left, and graduate student Jaime Taha-Tijerina, lead authors of a new ACS Nano paper on nanoparticle-infused transformer oils, show vials of the oils they say are up to 80 percent more efficient in keeping transformers cool. Credit Jeff Fitlow/Rice University

Researchers at Rice University have created a nano-infused oil that uses a very tiny amount of hexagonal boron nitride (h-BN) particles suspended in standard mineral oils to efficiently remove heat from a system.

Rice University scientists have created a nano-infused oil that could greatly enhance the ability of devices as large as electrical transformers and as small as microelectronic components to shed excess heat.

Research in the lab of Rice materials scientist Pulickel Ajayan, which appears in the American Chemical Society journal ACS Nano, could raise the efficiency of such transformer oils by as much as 80 percent with an environmentally friendly material.

The Rice team headed by lead authors Jaime Taha-Tijerina, a graduate student, and postdoctoral researcher Tharangattu Narayanan focused their efforts on nanofluids for energy systems. Electrical transformers are filled with fluids that cool and insulate the core and windings inside, as well as components that must remain separated from each other to keep voltage from leaking or shorting.

The researchers discovered that a very tiny amount of hexagonal boron nitride (h-BN) particles, two-dimensional cousins to carbon-based graphene, suspended in standard mineral oils are highly efficient at removing heat from a system.

“We don’t need a large amount of h-BN,” Narayanan said. “We found that 0.1 weight percentage of h-BN in transformer oil enhances it by nearly 80 percent.”

“And at 0.01 weight percentage, the enhancement was around 9 percent,” Taha-Tijerina said. “Even with a very low amount of material, we can enhance the fluids without compromising the electrically insulating properties.”

Taha-Tijerina, who was employed by an electrical transformer manufacturer in Mexico before coming to Rice, said others working on similar compounds are experimenting with particles of alumina, copper oxide, and titanium oxide, but none of the compounds has the combination of qualities exhibited by h-BN.

Narayanan said the h-BN particles, about 600 nanometers wide and up to five atomic layers thick, disperse well in oil and, unlike highly conductive graphene, are highly resistant to electricity. With help from co-author Matteo Pasquali, a Rice professor of chemical and biomolecular engineering and of chemistry, the team determined that the oil’s viscosity – another important quality – is minimally affected by the presence of the nanoparticle fillers.

“Our research shows that with new materials and innovative approaches, we can add enormous value to applications that exist today in industry,” Ajayan, Rice’s Benjamin M. and Mary Greenwood Anderson Professor in Mechanical Engineering and Materials Science and of chemistry. “Thermal management is a big issue in industry, but the right choice of materials is important; for transformer cooling, one needs dispersants in oils that take heat away, yet remain electrically insulating. Moreover, the two-dimensional nature of the fillers keeps them stable in oils without settling down for long periods of time.”

Reference: “Electrically Insulating Thermal Nano-Oils Using 2D Fillers” by Jaime Taha-Tijerina, Tharangattu N. Narayanan, Guanhui Gao, Matthew Rohde, Dmitri A. Tsentalovich, Matteo Pasquali and Pulickel M. Ajayan, 24 January 2012, ACS Nano.

DOI: 10.1021/nn203862p

Co-authors are Guanhui Gao, a visiting scholar in Ajayan’s lab; senior Matthew Rohde; and graduate student Dmitri Tsentalovich, all of Rice.

so to use minerail oil with 0.1 % he boron nitrate as an replacement for engine coolant water and ethylglycol would that not be to dense and cause esessive loading on water coolant pump so what is the right ratio for isopropel alcohol and minerial oil with boron nitrate. I have been standing by in abhoration as ill bet most of the glycol engine coolant is not recycled and is very evident as contaminant in espeacialy bull kelp denisties in the marine ocean enviorment