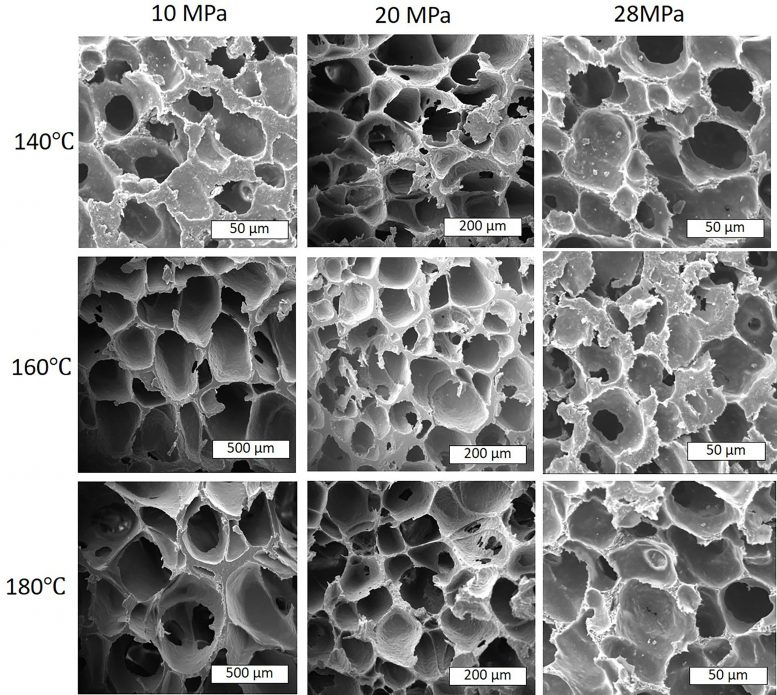

Foam structure for various temperatures and pressures. The bulkiest foams have the largest air pockets and are good for flotation devices. Credit: Heon Park

Scientists develop a method to reuse previously non-recyclable plastic.

Biodegradable plastics are supposed to be good for the environment. However, because they are specifically made to degrade quickly, they cannot be recycled.

Researchers have developed a method to turn biodegradable plastic knives, spoons, and forks into a foam that can be used as insulation in walls or in flotation devices. The method, by scientists from the University of Canterbury in New Zealand, has been published in Physics of Fluids, by AIP Publishing.

The investigators placed the cutlery, which was previously thought to be “nonfoamable” plastic, into a chamber filled with carbon dioxide. As pressure increased, the gas dissolved into the plastic.

When they suddenly released the pressure in the chamber, the carbon dioxide expanded within the plastic, creating foaming. Author Heon Park said the process is like opening a can of soda and releasing the carbonation.

“Tweaking temperature and pressure, there is a window where we can make good foams,” said Park. “It’s not that every temperature or every pressure works. We found what temperature or what pressure is the best to make those nonfoamable plastics into foams.”

Each time plastic is recycled, it loses a bit of its strength. Foams are an ideal new material, because they are not required to be strong in many applications.

“Whenever we recycle, each time, we degrade the plastics,” said Park. “Let’s say we have a biodegradable spoon. We use it once, and we recycle it back into another spoon. It may break in your mouth.”

The ideal structure of a foam depends on its final use. Bulky foams, which have large or plentiful air pockets, are good for buoys. The researchers found, contrary to what was previously thought, lower chamber pressures led to bulky foams.

Making biodegradable plastics recyclable could alleviate some of the global pollution problem. While biodegradable material eventually breaks down in nature, it is even better for the environment if plastics can be repurposed.

Biodegradable and recyclable plastics can be used more than once but are also less of an environmental threat if they end up in oceans or landfills. The team believes this process could be implemented on a large scale.

“We can expand foaming applications to a lot of plastics, not just this plastic,” said Park.

Reference: “Recycling and rheology of poly(lactic acid) (PLA) to make foams using supercritical fluid” by Lilian Lin, Young Lee and Heon E. Park, 29 June 2021, Physics of Fluids.

DOI: 10.1063/5.0050649

Hi Dears

We are a newly established start-up aiming for sustainable construction using maximum utilisation of technology and science in our manufacturing processes. Expandable foam is one of the primary consumable items in our wall and roof panels as heat/sound insulation. we desired to replace that with a green product like the foam you presented in this chapter. it would be appreciated if you answer our following question:

Is this foam available on a commercial scale(please introduce the manufacturers if possible)?

did it pass related standards like Fire resistance or hygienic?

Any additional information provided will be appreciated.

Sh. Azarbin

Director of Project

Robo Steel Prefab