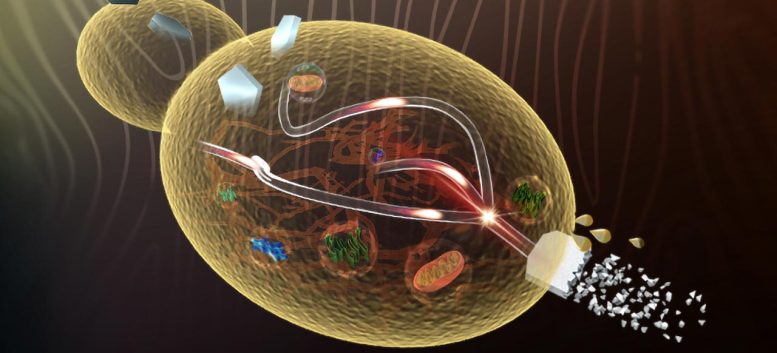

Fatty acids and 3-hydroxypropionic acid were efficiently produced by engineering co-utilization of glucose and xylose in Ogataea polymorpha for lignocellulose biorefinery. Credit: DICP

A team from the Dalian Institute of Chemical Physics has pioneered a microbial system that optimizes the production of valuable chemicals from lignocellulosic biomass by enhancing sugar co-fermentation.

Lignocellulosic biomass is a renewable feedstock for 2nd-generation biomanufacturing. In particular, efficient co-fermentation of mixed glucose and xylose in lignocellulosic hydrolysates is a key issue in reducing product costs.

However, co-utilization of xylose and glucose in microbes is challenging due to limited xylose assimilation and the glucose repression effect.

Recent Advances by DICP Researchers

Recently, a research group led by Prof. Yongjin Zhou from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences (CAS) has proposed a microbial platform for lignocellulose bio-refinery. It can efficiently synthesize acetyl-CoA derivatives, such as fatty acids (FFA) and 3-hydroxypropionic acid (3-HP), owing to the enhanced supply of precursor acetyl-CoA and cofactor NADPH by rewiring the cellular metabolism of Ogataea (Hansenula) polymorpha.

This study will be published today (August 24) in Nature Chemical Biology.

Technological Innovations and Results

The researchers successfully achieved the simultaneous utilization of glucose and xylose. They did this by introducing a hexose transporter mutant and xylose isomerase, and overexpressing the native xylulokinase to enhance xylose catabolism and import.

The engineered strain produced 7.0 g/L FFA from real lignocellulosic hydrolysates in shake flasks and 38.2 g/L FFA from simulated lignocellulose in a bioreactor. Furthermore, this superior cell factory was expanded for 3-HP production by a metabolic transforming strategy, obtaining the highest 3-HP titer of 79.6 g/L from simulated lignocellulose.

“Our work realized co-utilization of xylose and glucose without compromising native glucose metabolism and demonstrated the potential of O. polymorpha as a cell factory to produce versatile value-added chemicals from lignocellulose,” said Prof. Zhou.

Reference: “Engineering co-utilization of glucose and xylose for chemical overproduction from lignocellulose” by Jiaoqi Gao, Wei Yu, Yunxia Li, Mingjie Jin, Lun Yao and Yongjin J. Zhou, 24 August 2023, Nature Chemical Biology.

DOI: 10.1038/s41589-023-01402-6

Be the first to comment on "Innovative Lignocellulose Bio-Refinery: Yeast’s New Frontier in Value-Added Chemical Production"