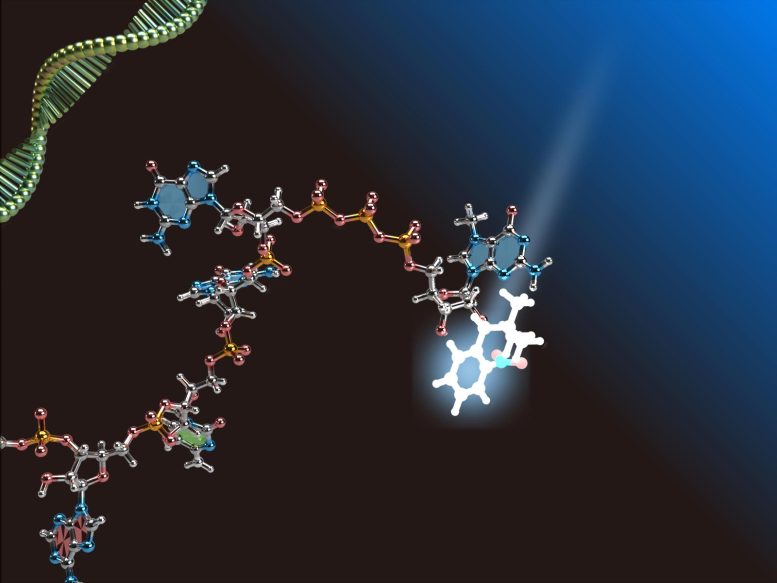

Pure capped mRNA vaccine opens the door to more effective vaccines with lower chances of inflammation. Credit: Mizuki Tada

A Japanese research team has introduced the ‘Purecap’ method, enabling the production of highly pure mRNA vaccines.

A research group from Japan has developed a method to produce highly active mRNA vaccines at high purity using a unique cap to easily separate the desired capped mRNA. This ‘Purecap’ technique extracted up to 100% pure Cap2-type mRNA, which showed 3-4 times better production of the protein that stimulates the immune system. These results open up the possibility of purer vaccines with a lower risk of inflammation caused by impurities. Their findings were published recently in the journal Nature Communications.

Potential of mRNA Vaccines

mRNA vaccines have been used successfully as therapy against variants of the coronavirus. This has given researchers hope for their future use as a cancer vaccine. However, the purity of vaccines hinders this goal because impurities can trigger the immune system. This may cause inflammation around the injection site, a common side effect of vaccination.

Understanding Vaccine Impurities

Impurities in mRNA vaccines are often introduced in the capping stage. During this stage, a cap structure is added that improves the translation of mRNA and protects and stabilizes it. Caps can only be added to single-stranded mRNA, so ideally a vaccine should contain 100% pure single-stranded mRNA. However, unwanted double-strands of mRNA may be present, reducing its purity.

As single- and double-stranded mRNAs have different properties, they can be separated using a technique called reversed-phase high-performance liquid chromatography (RP-HPLC). This technique separates mRNAs on the basis of their hydrophobicity or hydrophilicity, i.e., their repulsion to or attraction to water.

Research Methodology and Findings

A research group led by Professor Hiroshi Abe, Project Assistant Professor Masahito Inagaki, and Project Associate Professor Naoko Abe of the Graduate School of Science, Nagoya University, in collaboration with Tokyo Medical and Dental University, used a unique PureCap method to introduce a hydrophobic tag at the capping stage. The tagged mRNA was easily separated at the RP-HPLC stage. The tag was then easily removed by light treatment, resulting in a 98%-100%-pure vaccine.

“We were very excited about the result when we saw on the chart that the RP-HPLC process had separated completely the capped and uncapped RNAs,” Hiroshi Abe said. “For a coronavirus mRNA, which is 4247 bases long, we successfully used the PureCap method to produce capped mRNA with over 98% purity.”

The research group paid particular attention to a group of cap structures that exist in animal and plant cells, called Cap0, Cap1, and Cap2. Although Cap2 is found in animal and plant cells, the evaluation of its function has been difficult because there was no way to obtain pure capped mRNA to ensure a fair test.

“The Cap structure used in mRNA vaccines has so far been limited to Cap0 and Cap1 types. However, we used our technique to manufacture Cap0, Cap1, and Cap2-type structures,” Abe said. “Highly purified Cap0, Cap1, and Cap2-type mRNA synthesized using the PureCap method showed lower immunostimulatory activity compared to mRNAs synthesized using conventional techniques showing their potential use in pharmaceuticals.”

As viruses mostly produce Cap1 mRNA, the immune system is less stimulated by Cap2. This suggests that a vaccine that uses Cap2 would be less likely to cause unwanted side effects such as inflammation when it is injected. However, it would still be able to create viral proteins when transcribed that make the vaccine effective.

Benefits of the Cap2 Structure

The group used Purecap to create Cap2 mRNA and analyzed its protein synthesis capacity. They found that Cap2 mRNA produced 3-5 times more protein than Cap1 mRNA, which would enhance the immune response. They also showed that their Cap2-type mRNAs caused lower stimulation of the inflammatory response than mRNAs synthesized using conventional techniques.

“Conventional mRNA vaccine production methods could not prepare capped mRNA with high purity, raising concerns about reduced protein synthesis and impurity-derived inflammatory reactions,” Abe said.

“The PureCap method solves these problems by selectively purifying only capped mRNA. Furthermore, the Cap2-type structure created using this technique is more efficient in protein synthesis and less irritating to the immune system. This technique has the potential to improve the safety and efficacy of mRNA vaccines. It is a revolutionary advance toward the practical application of mRNA medicine, as well as deepening our understanding of the fundamentals of mRNA science.”

Reference: “Cap analogs with a hydrophobic photocleavable tag enable facile purification of fully capped mRNA with various cap structures” by Masahito Inagaki, Naoko Abe, Zhenmin Li, Yuko Nakashima, Susit Acharyya, Kazuya Ogawa, Daisuke Kawaguchi, Haruka Hiraoka, Ayaka Banno, Zheyu Meng, Mizuki Tada, Tatsuma Ishida, Pingxue Lyu, Kengo Kokubo, Hirotaka Murase, Fumitaka Hashiya, Yasuaki Kimura, Satoshi Uchida and Hiroshi Abe, 11 May 2023, Nature Communications.

DOI: 10.1038/s41467-023-38244-8

Be the first to comment on "The Future of Vaccines? Japan’s Breakthrough in 100% Pure mRNA Production"