Rice University secures federal funding to enhance advanced materials research focusing on improving 2D materials production, studying composite material interfaces, and exploring chemical reactions in nonequilibrium states for industrial and security applications. Credit: SciTechDaily.com

Rice University’s Boris Yakobson has received over $4 million in federal funding to advance research on 2D materials, interfaces in composite materials, and nonequilibrium chemical processes.

His work aims to develop better production methods, understand material behavior under extreme conditions, and explore new material synthesis for applications in energy and defense technologies.

Advanced Materials Research at Rice University

Advanced materials are an important point of innovation for areas critical to national security such as energy, defense, aeronautics, and aerospace technologies. Rice University materials scientist Boris Yakobson has won three awards from two federal agencies totaling $4,140,611 over several years to research challenging aspects of advanced materials’ production, performance and dynamics.

The awards are representative of Rice as a nationally relevant site of materials science research. Yakobson said he hopes the projects, which build on prior work, “lead to discoveries that really transform how we understand, make, and work with advanced materials.”

Boris Yakobson is Karl F. Hasselmann Professor of Engineering and a professor of materials science and nanoengineering. Credit: Jeff Fitlow/Rice University

Exploring Production Techniques for 2D Materials

A project titled “Mapping the synthetic routes for 2-dimensional materials” aims to unravel the molecular mechanisms that would enable the production of 2D materials for use in microchips and future electronics at industrial scale and quality.

2D materials were first produced through exfoliation, or by “peeling off” atom-thin layers from a three-dimensional ⎯ or bulk ⎯ crystal, but this production method is impractical for scale-up. Chemical synthesis-based production methods rely on a precise understanding and control of chemical reactions resulting in the growth of crystal layers. Often, production methods entail the transformation of the material from a solid into vapor and back into solid form.

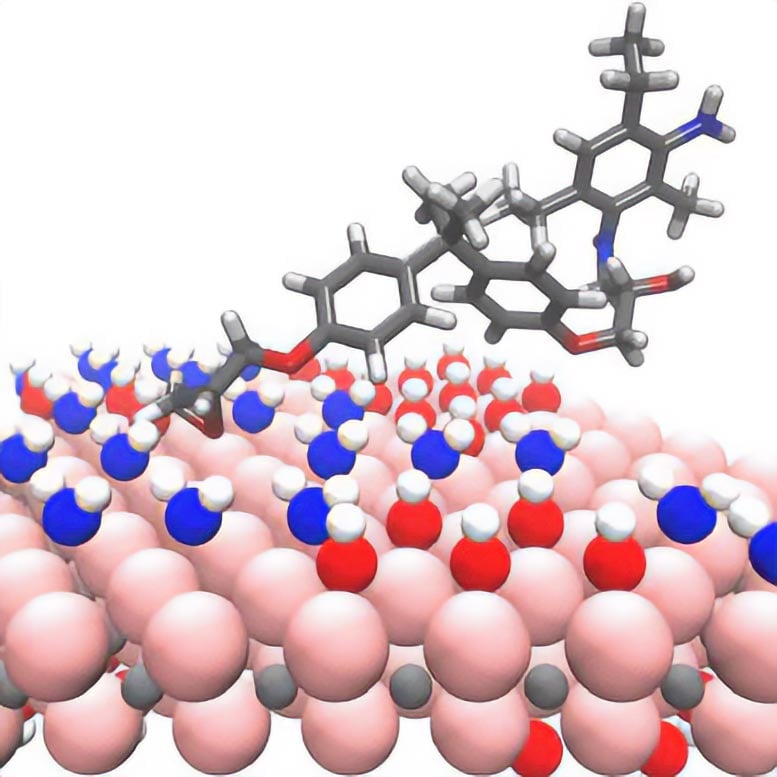

Representation of an interface in a composite material. Credit: Yakobson Research Group/Rice University

The Role of Quantum Dynamics in Material Synthesis

“Solid-vapor-solid reactions are many and poorly understood, and scientific breakthroughs in several key examples must pave the way to new science at the crossroads of gas-phase reaction kinetics, nonequilibrium surface physics and emergent crystal structure,” said Yakobson, who said he plans to use computational methods to explore initial quantum-level molecular dynamics in order to identify the key transformations leading from raw precursors to intermediate species and ultimately to building units that assemble into the target crystal layer.

“We are trying to answer questions such as can we accelerate crystal growth by adding extra components without compromising the quality of our product, or how can we create desired defect types in our resulting material that we can then use as current carriers, catalytic centers or single-photon emitters for qubits in a quantum computer,” Yakobson said.

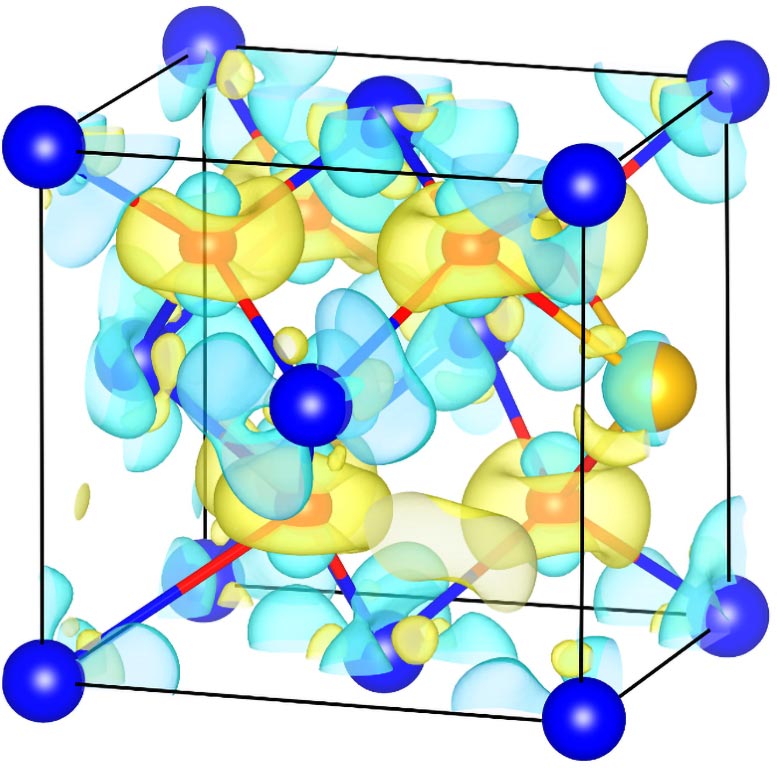

“Electronic glue” holds the atomic lattice of a ceramic material exposed to extreme heat and radiation, when the constituent ions change their charges and mobility. Credit: Yakobson Research Group/Rice University

Strategic Directions in Material Synthesis Research

Building on previous work on several iconic 2D materials such as graphene, molybdenum disulfide, and hexagonal boron nitride, the Yakobson Research Group aims to establish a general approach to the development of predictive synthesis models for perovskites, nitrides, oxides and other materials coveted for energy and electronics applications.

“We also aim to automate the search for reaction paths that would allow us to synthesize new, previously unknown materials or to simplify the production of materials like borophene, which now require expensive or esoteric techniques,” said Yakobson, whose proposed work on 2D materials will be supported by $2,107,997 over several years from the U.S. Department of Energy.

Advancements in Composite Material Interfaces

The Yakobson Group was also awarded a combined $2,032,614 over the next four years from the U.S. Department of Defense for two projects — one looking at interfaces in composite materials and another on the behavior of energetic materials in extreme nonequilibrium states.

“One of these projects looks at the atom- or molecular-level details of how interfaces — the borderlines between microcomponents in a mixed solid — respond to extreme load,” Yakobson said.

Interfaces impact the overall performance of composite materials, and properties such as mechanical strength, toughness, electrical resistivity and thermal and corrosion stability are of critical importance in both civil and defense infrastructure and applications from bridges and railroads to submarines and supersonic aerospace vehicles.

“We plan to use state-of-the-art quantum chemistry computations to look at heterogeneous interfaces in order to determine how high-performance composite materials behave under extreme conditions and how we might improve their design,” Yakobson said.

Challenges and Innovations in Nonequilibrium Chemical Processes

The second DOD-sponsored project will focus on developing ways to quantify the rates of chemical reactions and other processes that occur in complex systems in states far from chemical equilibrium.

“Systems that are far from thermodynamic equilibrium will exhibit significant spatial variations or gradients in terms of energy density, chemical composition and more, making it difficult to determine the speeds of processes,” Yakobson said. “This is very important to know, especially for energetic materials, which are a broad class of materials that store a large amount of chemical energy.”

Examples of energetic materials include explosives, fuels and propellants. Drawing on insights from solid state chemistry, Yakobson seeks to “make a dent” in the relative dearth of knowledge on how stress-mediated reactions and the spatial heterogeneity of nonequilibrium systems play out in gas- and liquid-phase processes.

Conclusion and Future Outlook

“Harnessing modern computational technology will be immensely valuable for this project,” Yakobson said. “We hope to advance from near-equilibrium science operating with, say, temperature gradients to modern dynamics of quantized phonons, vibrons, excitons … and their coupling as the new toolset for describing the energy game far away from equilibrium.”

The content in this press release is solely the responsibility of the authors and does not necessarily represent the official views of the funders.

Be the first to comment on "Atom-Level Innovations: Rice’s Big Bet on Advanced 2D Materials"